DOs and DONTs when working with System Liquid

This article will explain how to prime the system liquid and keep the containers clean to keep the performance of your instrument high.

The liquid system of a liquid FCA is filled with liquid which we refer to as system liquid. This liquid is used as a wash fluid and/or diluent.

When refilling the system liquid containers, one should follow the recommendations below:

- The system liquid must be free of particles.

- Make sure that the system liquid container is clean.

- The system liquid must be free of air bubbles and must be room temperature.

- To reach optimal pipetting performance we recommend degassing the system liquid. This can be achieved by refilling the container the night before use, to allow natural degassing overnight.

- In order to ensure that during the operation no air bubbles form in the pipetting tubing, a sufficient quantity of system liquid must circulate through the liquid system. We recommend at least 60 ml per hour. Any additives to the system liquid must be validated to evaluate the influence on the pipetting performance and the overall analytical process.

The standard liquid used is deionized or distilled water with a conductivity between 0.5 uS/cm and 10 uS/cm. In special cases, you can have a DMSO as a system liquid. However, pass-fail criteria for standard Operational Qualification (OQ) procedures are based on a water-filled system. Either the liquid system must be returned to the water for those service qualifications, or a test must be created and approved for such use by the lab.

How to clean System Liquid Container and Waste Container

To clean the liquid container and the waste container, proceed as follows:

- Before you start, ensure that a cleaning agent from the system care table is available.Empty the wash liquid container manually.

- Clean the liquid container in a sink basin with the cleaning agent and rinse.

- Disinfect the liquid container with alcohol.

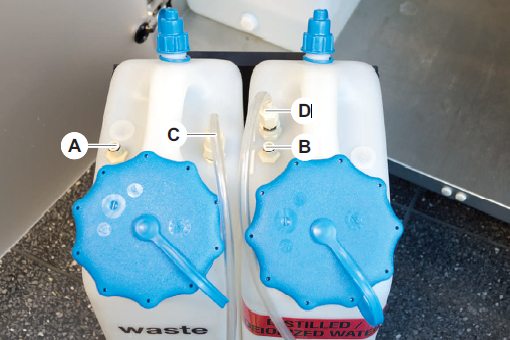

- Connect the system liquid and the waste container; liquid detection system (A,B) and tubes (C,D) are connected correctly

Further Help

For further help, please refer to our Helpdesk.

.

Link to Tecan Product Page:

Fluent® Automation Workstation

401815-016