EVOlution™ displays the liquid level detection (LLD) error: No liquid detected

This issue can be fixed by checking the liquid levels, the ground connection, and the DiTi cones.

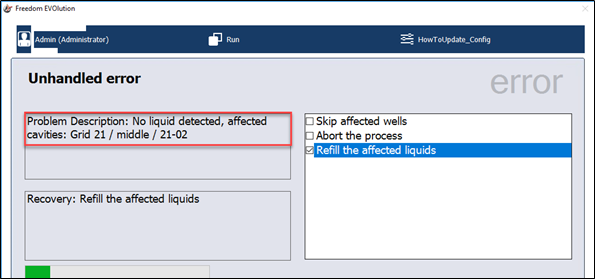

During a run, the software displays the error message “No liquid detected”:

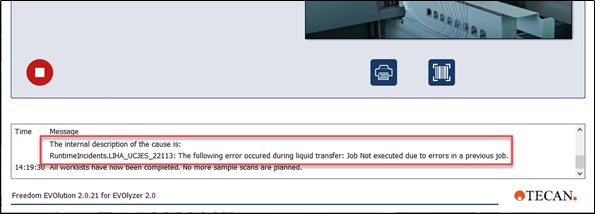

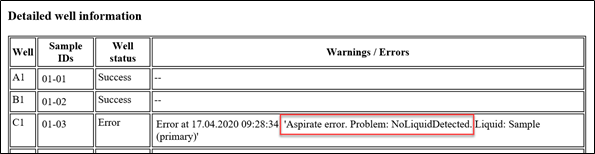

Alternatively, if this error handling option is selected in the liquid class editor, the affected well is skipped and a message is displayed in the ticker as well as later in the process report:

Usual root causes

1) Not enough liquid in the container

2) Bad ground connection of the carrier

3) Dirty tips or DiTi cones

Usual solutions

1) Check the liquid level and add liquid if necessary.

2) Place the rack correctly on the carrier and clean the carrier to ensure a good connection and clear contact between the container, rack carrier and worktable:

a. Remove the carrier from the worktable and wipe the surface with a suitable cleaning agent. Make sure not to damage the labels on the carrier with the cleaning agent.

3) Clean the tips or DiTi cones (refer to the operating manual for details):

a. Touch the worktable before touching the DiTi cones to discharge static electricity from your body.

b. Wipe the DiTi cones with a lint-free tissue dampened with alcohol.

Next steps if the issue cannot be resolved:

- Note your serial number. Where can I find my serial number?

- Create a service request.

Link to Tecan Product Page:

401814-003