Troubleshooting a misaligned Flexible Channel Arm (FCA)

This article describes how to troubleshoot a misaligned FCA in Fluent Control.

Misalignment of the FCA can be associated with the labware on the single or several carriers. Depending on which issue you are facing please follow the troubleshooting steps below.

Tips not aligned with the labware on a single carrier

Possible cause:

- Carrier in wrong position

- Segment not locked in place

- Labware not positioned correctly

Corrective measures:

- Please make sure the labware is correctly placed on the carrier, e.g. fits perfectly in the black fittings on the carriers.

- Ensure correct carrier position

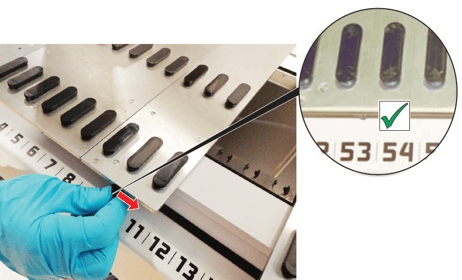

To load runners, proceed as follows:

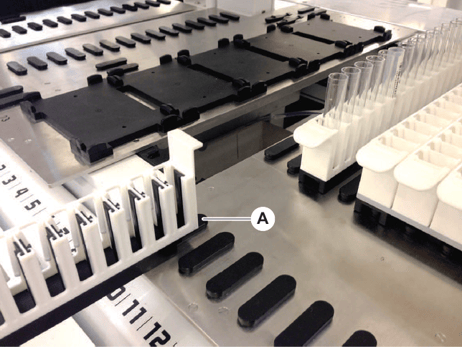

- Align the runner with the respective grid position (A).

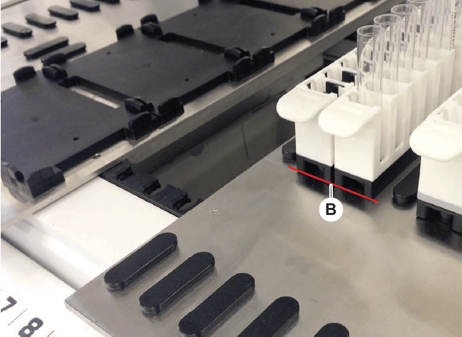

- Push the runner to the stop position.

- Ensure that the runner locks the segment securely.

This can be felt in the last couple of millimeters before the runner touches the

stop position.

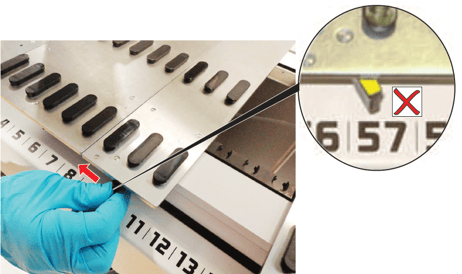

To unload runners:

- Pull the runner horizontally at the level of the deck until fully removed from the loading area.

- Support the front end of the runner with one hand.

- Ensure that the runner clears all pins before lifting the runner

- Lock segment in place

Figure 1. Segment closed

Figure 2. Segment opened

Tips not aligned with the labware on several carriers

Possible cause

Defective arm alignment caused by a collision.Improperly thought custom labware

Corrective measures

Check the teaching for the non-default labware.

Please consult customer support.

Further Help

For further help, please refer to our Helpdesk.

401815-020