Troubleshooting for ‘’No Liquid Detected” or “Not Enough Liquid Detected”

This article will help you to troubleshoot issues when no or not enough liquid is detected in the pipetting wells.

The incorrect handling of liquids can lead to various errors. For example, the user prompt “No Liquid Detected” or “Not Enough Liquid Detected”, can be prompted with different root causes. Since the instrument consists of various components, all the components must be taken into consideration. The components one should check are:

- Software (Labware Teaching, Liquid Classes)

- Liquid Properties (Bubbles present, Foam building, Viscosity)

- Hardware (Detection Mode pLLD,cLLD)

Software

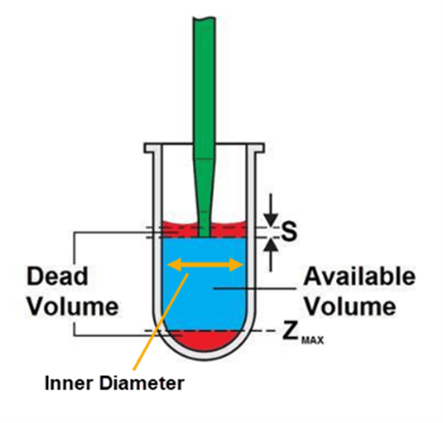

Teaching the Labware is one of the most important points and special attention must be given to the Z-Values. Z-values and labware definition play a major role in the liquid handling and calculation of the volume content because they define the available pipetting volume and the so-called dead volume.

These values can be checked and corrected in the Edit Labware tab in the Freedom EVOware® software. When troubleshooting please check:

- Z-Values (Z-Start, Z-Dispense, Z-Max)

- The diameter of the Labware

- The shape of the Labware (96 Well Microplate, Round-Bottom-Shape, V-Shape, Flat-Bottom-Shape)

Figure 1: Calculation of the available and the dead volume

Figure 1. shows the parameters used in the calculation of the volume available for the aspiration. The available volume is represented in blue, while red indicates the so-called ‘’dead’’ volume which is not available for pipetting (volume below Z-max and above the submerge depth).

Liquid Properties

The liquid properties play a role in detection as well as aspirating and dispensing of the liquid. This can have a major impact on the pipetting accuracy and precision. Therefore, it is important to check the liquids for bubbles, foam as well as if they are highly viscous. Additionally, one should verify the sensitivity level defined in the software

Another important factor is to perform a daily maintenance, for more information, please see Knowledge Portal Document: EVOware Daily Maintenance.

Please find below two possible error scenarios and their potential root causes:

Scenario 1:

„No liquid detected “- Potential root causes

- No liquid inside the well

- The electrical circuit through the frame is not closed

- Check the hardware - Tip adapter, carrier

- Inaccurate detection of liquid level

- Check the conductivity setup in the liquid class, i.e. very good, good, bad

- Check the submerge depth, and the Z-Start in the software

- Check the liquid itself for bubbles, foam, evaporating reagent

Scenario 2:

“Not enough liquid detected” - Potential root causes:

- Inaccurate tracking or calculation of liquid volume

- Check the diameter of the tube in the software

- Not enough volume available

- Check the Excess Volume, Conditioning Volume, Airgaps, Calibration in the liquid class

- Dead Volume is too high

- Check the submerge depth and the Z-max in the software and if needed consider adjusting the shape of the labware

Hardware

If there is still no improvement, the issue might be with the hardware itself. The cLLD or pLLD cables might be defective. This issue cannot be resolved without help of the Field Service Engineer.

Further Help

For further help, please refer to our Helpdesk.

Link to Tecan Product Page:

401812-016