Troubleshooting Liquid level detection errors

This article will help you to troubleshoot the issues when not enough liquid is detected in the pipetting wells.

The FluentControl™ software generates exception messages if detection and aspiration do not behave as expected. Two types of messages can be displayed:

- No liquid detected

No liquid is detected, either because the well is empty, or the liquid cannot be detected with the selected level detection method or settings. Please check that enough liquid is present in the wells and select the correct liquid level method or setting in the liquid class. Verify the DiTi cones are properly tightened.

- Not enough liquid

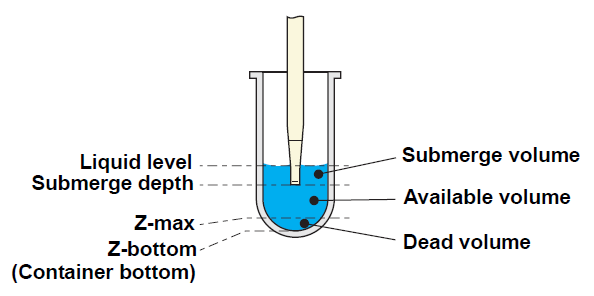

The volume of liquid available (calculated from the detected liquid level, the submerge depth, Z-max and well geometry) is smaller than the requested aspiration volume (Figure 1.). Please check the well geometry, submerge dept and Z-max.

Note: The dead volume cannot be aspirated. The amount of dead volume in a container depends on the geometry of the container.

- Failed level detection

The exception message is generated when

-

- The labware, the carrier or the tip is not suitable for the capacitive liquid level detection (cLLD). Please check that you are using the conductive DiTi’s (not transparent). Place the labware only on the carriers suitable for the cLLD.

- Droplets have formed on the tip orifice before the tip has reached the actual liquid level. Please check there is no liquid outside the well as well as tighten the DiTi cones.

- The cLLD signal is persistently disturbed by electrostatics or electromagnetic interferences or by the presence of bubbles on the liquid surface. Please make sure there is not bubbles on the liquid surface as well as no static electricity or electromagnetic interference in the area around the instrument.

- The wrong sensitivity group has been selected in for the liquid (AST only). Please check the liquid class and set it up according to the liquid properties.

The following exception messages are generated by the special features of the cLLD:

- Aspiration supervision failed

This exception message is generated when an unexpected detection exit signal during aspiration occurs. Please check there is no bubbles at the liquid surface as this can lead to air aspiration. Please check that correct labware dimensions are defined, incorrect labware dimensions result in erroneous tracking.

- Tip occlusion

This error messages related to the tip retract supervision. Please check that the affected tips are not occluded, there are no bubbles at the liquid surface, and the correct labware definition is used.

- No exit

This exception message relates to the tip retract supervision and is generated where there was no exit signal during the tip retraction. Please check the sample for the foam and above-mentioned parameters as this can be provoked when air is completely or partially aspirated.

Further Help

For further help, please refer to our Helpdesk.

401815-018