Troubleshooting Pressure Monitored Pipetting (PMP) errors

This article gives a short overview of Pressure Monitored Pipetting and how to troubleshoot errors that can be triggered during the aspirate and dispense command.

The Pressure Monitored Pipetting (PMP) is an Add-on on the Freedom EVO®, operated by the Freedom EVOware® application software. It is designed and verified to monitor pressure changes during pipetting operations to detect errors such as clots and air aspiration ---. The PMP is available for the Air LiHa and Liquid LiHa. However, the Multisense Option is also needed if PMP is implemented on the Liquid LiHa.

PMP Errors can have different causes. Since the instrument consists of various components, all components must be taken into consideration. The components to check as possible source of error are:

- Software (Liquid Class, Pipetting Sequence)

- Liquid Properties (Foamy, Viscosity, Bubbles)

- Hardware (USB, Ilid Cable, Tip adapter, Pressure Sensor)

- Sample related

Software

Various configurations must be considered to check if it is a Software issue.

- The correct Liquid Class must be used and there is a special Liquid Class to use the PMP. When customizing a PMP liquid class, a PMP liquid class must be used as the template.

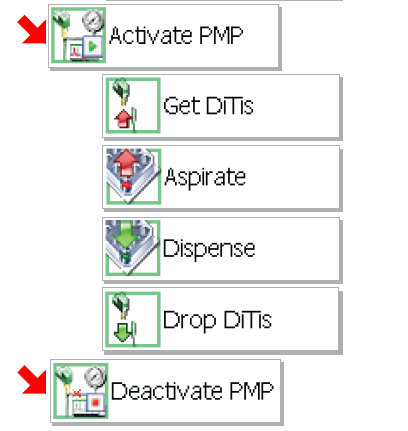

- When writing a pipetting script, PMP must always be activated at the beginning and deactivated at the end of the sequence. See Figure 1. which illustrates how to activate and deactivate the PMP for the pipetting sequence.

Figure 1. Activation / Deactivation of PMP during a pipetting sequence

Liquid properties

Check the liquid properties as they play a role in the detection as well as aspiration and dispensing of the liquid. Therefore, it is important to check the liquid for bubbles, foam, clots, and if they have high viscosity. This can have a major impact on the liquid level detection and the PMP which causes errors during the run. Please be aware that PMP works only with cLLD and cannot be used ofr 10 ul or less volume.

Hardware components

There are different Hardware components needed to use the PMP option.

- A) The specified USB connection to the computer and a Tip adapter is needed for the correct liquid level detection and PMP operations.

- B) Tip adapters / Ilid cables

- Air LiHa : The tip adapter for the AirLiHa relates to two ilid cables: One is connected to the cLLD board and the other to the PMP/pLLD board.

- Liquid LiHa: The tip adapter for the Liquid LiHa is connected by one ilid cable: this cable is connected to the cLLD board.

If any of the ilid cables is broken, or if there is no USB connection, Freedom EVOware will show a PMP error.

Sample Related and Non-Sample Related Errors

The typical error messages for non-sample related errors when using PMP are:

i. Aspiration Errors:

The issue for an aspiration error can be complete or partial aspiration of air, clogged pressure channel or system leakage.

If this occurs, please check

- The STAG (System Trailing Airgap) is large enough (only applicable for Liquid LiHa PMP)

- Run the Pressure Sensor Test to check for possible pressure sensor damage, using the instrument software and the test tool

- Run the Leakage Test to check for possible pressure system leakage, using the instrument software and the test tool

- Verify that the submerge depth is at 1 – 2 mm during the aspiration and adjust if necessary

ii. System Errors:

System error appear during the initialization and are related to the PMP USB hub. The reason for a system error can be due to the PMP range restrictions not being met. Another reason could be that data communication issues prevent PMP from completing the pressure curve evaluation within 10 seconds after the end of the diluter movement.

If this occurs, please check:

- The delays settings in the liquid class are within the restricted ranges

- Resources of your computer are sufficient (Memory, RAM)

- All USB cables are properly connected

- Remove any USB device which is not used by the Freedom EVO system

- The Freedom EVO instrument and USB options are displayed in the section “Tecan USB Device” of the Windows device manager

iii. Dispense Errors:

These errors are displayed when a PMP error is detected during dispense.

If this occurs, please check:

- All delay settings are within the restricted ranges

- Tip does not touch the bottom or the walls of the cavity during dispense

iv.“Pressure out of Range” Error:

This error is typically caused by incorrect teaching of the labware.

If this occurs, please check:

- The teaching and that the tip is not too close to the bottom or the sides of the well

- The Aspiration and Dispense Speed is not too high for the type of Liquid.

- The Application Software must know if Filter or Non-Filter DiTis are in use, otherwise this can cause this error

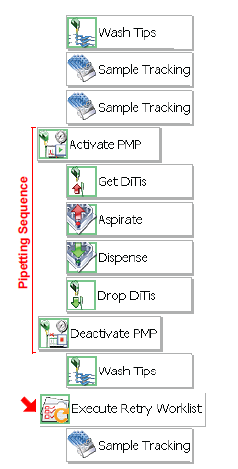

After a run with errors there is a possibility to use the “Execute Retry Worklist” command. This will automatically create a worklist to retry the pipetting sequence after pipetting was halted due to an error detected by PMP on aspiration or a PMP instrument error. In Figure 2. there is an example on how to set the “Execute Retry Worklist” command.

Figure 2. Script example for ‘’Execute Retry Worklist’’

Further Help

If the issue persists, please contact your local Helpdesk for further help.

Link to Tecan Product Page:

401812-017