Biofoundries are advanced facilities that integrate high-end equipment and skilled people with automation, synthetic biology, and high-throughput technologies, providing the infrastructure to engineer biological systems systematically, transforming biotechnology and synthetic biology workflows. Researchers from Stellenbosch University, one of the top Universities in Africa, have established Africa’s first academic biofoundry – the Stellenbosch Biofoundry.

The Stellenbosch Biofoundry Team - From left to right: Gerhardt Coetzee, Heinrich Volschenk, Monique Barnard, Kim Trollope, Dug Rowland, Odwa Jacob, Stefan Kühn, Johann Gӧrgens, David Morrison. Photo credit: Peartree Photography.

The Stellenbosch Biofoundry Team - From left to right: Gerhardt Coetzee, Heinrich Volschenk, Monique Barnard, Kim Trollope, Dug Rowland, Odwa Jacob, Stefan Kühn, Johann Gӧrgens, David Morrison. Photo credit: Peartree Photography.

Improved biotechnology infrastructure: an unmet need

The Stellenbosch Biofoundry exemplifies how automation and interdisciplinary collaboration can transform biotechnology in resource-limited settings. Its founders, Dr Trollope and Professors Volschenk and Görgens, through working together on numerous projects, identified an urgent need to expand local capabilities in key bioengineering processes.

Having limited access to lab facilities during the COVID-19 pandemic further emphasized the importance of automation and self-sufficiency in ensuring a sustainable approach to biotechnology workflows. The Stellenbosch Biofoundry not only addresses infrastructure gaps but also unlocks value from South Africa’s existing scientific expertise and creates a platform to support start-ups, enable innovation, and contribute to the growth of the country’s bioeconomy.

Tecan provides a wide range of products to meet the automation demands of biofoundries to improve workflows, reduce costs and accelerate timelines.

The design-build-test-learn approach

The core framework of the Stellenbosch Biofoundry follows the Design-Build-Test-Learn (DBTL) model:

- Design: Implementing computational modelling to design genetic constructs or other metabolic elements that are the focus of study

- Build: Physically constructing genetic or metabolic material integrating automation at key stages

- Test: Performing high-throughput experiments to test the engineered system

- Learn: Employing machine learning to analyse data from experimental tests and refine subsequent experiment iterations

“This approach accelerates biomanufacturing timelines from years to months, enabling rapid prototyping of engineered organisms for a range of applications including pharmaceuticals, biofuels, and precision fermentation,” commented Dr Kim Trollope, Senior Researcher and Biofoundry Lead, Stellenbosch Biofoundry.

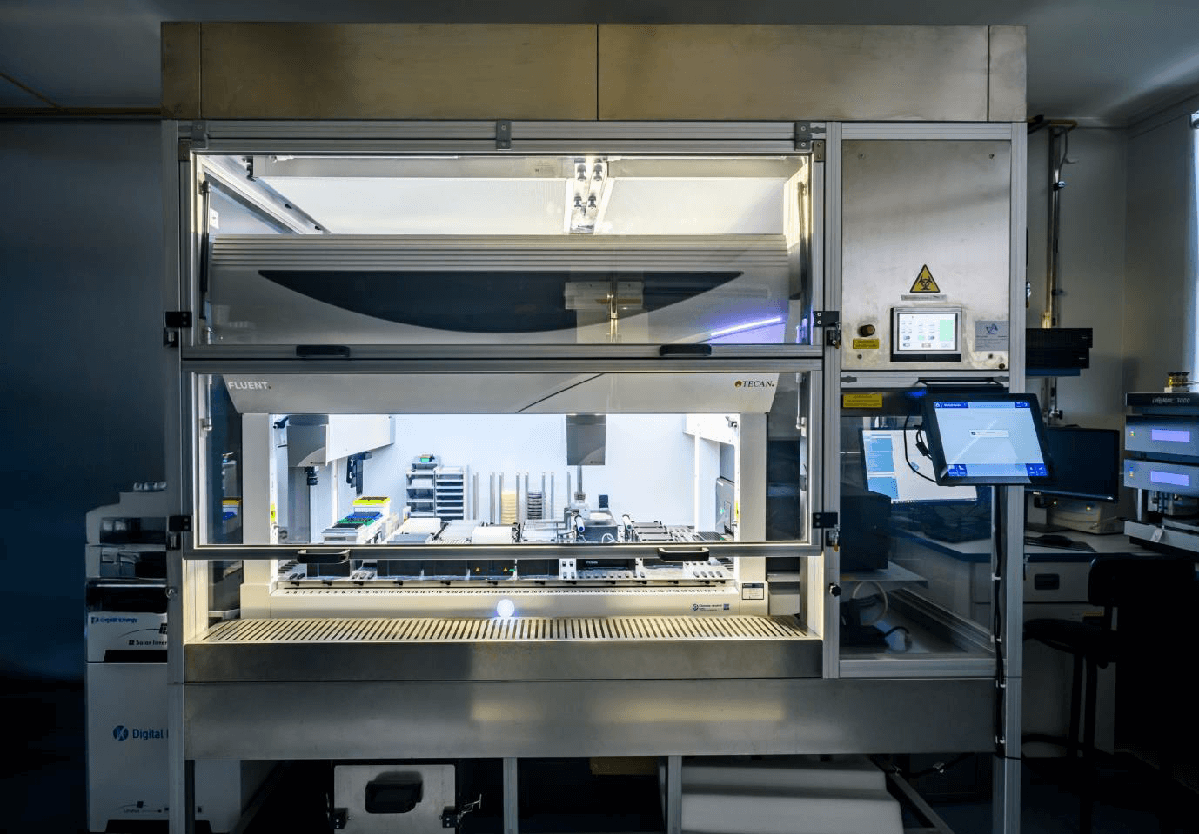

Tecan’s Fluent® 780: a modular and precise approach to automation

With a fully modular, open architecture, Tecan’s Fluent® 780 can be individually configured to help scientists meet throughput, cost saving and productivity goals. Through its global distributors, Tecan provides localized support to customers across the world.

“With Tecan’s Fluent® 780 we can engage the different system modules to suit our varied experimental needs. The precise pipetting of Tecan’s Fluent® 780 reduces human error and ensures precision in our experimental set-up. The option to house the unit within a Biosafety Level 2 hood and the commitment from Tecan’s local distributor to provide on-the-ground support were essential deciding factors, ensuring we received prompt service and maintenance despite its geographic distance from Tecan's European headquarters,” said Mr Dugald Rowland, Automation Specialist, Stellenbosch Biofoundry.

Dr Trollope added, “Being able to integrate third-party devices, such as the SciRobotics colony picker and plater, into this platform was essential for us as this streamlined and automated strain engineering workflows. The relatively simple software interface and accessible programming are an added advantage of using Tecan’s system. The Fluent® 780’s compact footprint was a key benefit given our limited lab space.”

The Stellenbosch Biofoundry’s design emphasizes automated workflows to streamline microbial strain development and accelerate drug discovery. Tecan’s Fluent® 780’s ability to process up to 48 microplates simultaneously is a key driver of the high-scale, automation capability of this facility.

Stellenbosch Biofoundry’s Tecan Fluent® 780. Photo credit: Peartree Photography.

Stellenbosch Biofoundry’s Tecan Fluent® 780. Photo credit: Peartree Photography.

Navigating the Establishment of a Biofoundry

Setting up a biofoundry requires careful planning and significant investment. The first steps are conceptualization, business plan development and fund raising. The Stellenbosch Biofoundry secured grant support in 2023 with contributions from the National Research Foundation’s National Equipment Program (grant number 150447), South African Medical Research Council, Stellenbosch University, Elma Foundation and South Africa’s Department of Science, Technology and Innovation, which enabled the facility set-up to progress.

With a plan in place and initial funding secured, the next stage involved creating a dedicated space within an existing laboratory and delivery of the first equipment pieces, which the Stellenbosch Biofoundry achieved over the course of 2023 and 2024.

To move from equipment installation to operation, requires automated workflow set-up and operator training. Since 2025, the Stellenbosch Biofoundry has been offering a range of biotechnology services including automated DNA assembly and cloning, in vitro transcription and RNA synthesis, assay design and development and bioactivity testing. For a truly successful biofoundry, refinement and optimization of service offerings is key. This requires further fundraising to enable the acquisition of additional equipment to expand the range of services.

Securing funding requires clear justification of the applications and benefits of what a biofoundry will enable. It may be necessary to combine strategic grants from multiple funders, including grant funding and academic and industry contracts. “Communicating that we were establishing a multifunctional platform, with a versatile setup to ensure long-term sustainability, rather than one dedicated to a narrow set of workflows, e.g. DNA sequencing, was a key selling point to funding bodies supporting our Biofoundry,” said Dr Trollope.“

Benefits and applications of biofoundries

Through the automation of repetitive tasks, biofoundries reduce human error and enable traceable, large-scale experiments. This frees up researchers’ time enabling them to focus on data analysis and other intellectual tasks. The high-scale nature of these facilities improves experimental outcomes by parallelization that simultaneously tests multiple elements under various experimental conditions.

Biofoundries reduce research and development costs through adopting a shared user model where multiple users can make use of the infrastructure of these facilities to increase the efficiency, accessibility and scalability of their synthetic biology workflows. “The Stellenbosch Biofoundry is open to the global community and offers services to researchers in academia and industry,” commented Mr Rowland.

These facilities play a key role in supporting education through training operators in interdisciplinary synthetic biology and robotics skills. In addition, Stellenbosch’s facility runs training for interns and students alongside its service offerings.

Available to academics, startups and established companies the Stellenbosch Biofoundry supports high throughput activities such as yeast strain engineering and screening focused projects. “Our approach also enables bioprospecting experiments – the high throughput capabilities of our facility support the screening of biological materials or biochemical compounds from nature that have the potential to be applied to medicine, agriculture and biotechnology,” added Mr Rowland.

Stellenbosch Biofoundry team members using the Tecan Fluent® 780. Photo credit: Peartree Photography.

Collaborating to drive local healthcare solutions in Africa

The establishment of the Stellenbosch Biofoundry has involved a network of people and through a range of partnerships the biofoundry is continuing to collaborate to transform biotechnology and synthetic biology. Stellenbosch’s Biofoundry capabilities will enable partners to translate basic research into tangible biotechnological solutions, such as reagents for vaccine development, diagnostics, and other medical technologies. This initiative will support the development of African-manufactured biological countermeasures.

The Stellenbosch Biofoundry is a member of the South African mRNA Vaccine Consortium (SAMVAC) and has been working on a project running from 2022-2025 entitled ‘Securing local reagent supply: in vitro transcription (IVT) enzymes production for mRNA vaccine synthesis and pandemic preparedness’. This project is linked to the mRNA Technology Transfer Programme with the hub situated in Cape Town, South Africa. The project provided the catalytic funding to support the establishment of the Stellenbosch Biofoundry, and the facility has developed workflows to automate yeast engineering, clonal selection and a suite of fluorescence-based assays for IVT and capping enzymes.

The Stellenbosch Biofoundry is currently working with a commercialisation partner on the Vaccines for Africa: Roll-out and production in South Africa (SAVax) to bring IVT raw materials to market. This measure is funded by the German Federal Ministry for Economic Cooperation and Development (BMZ) and European Union (EU) and supported by the Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH*.

Stellenbosch University has also opened LaunchLab CERI BIO, a biotechnology laboratory for biotechnology startups. The Stellenbosch Biofoundry will work closely with this laboratory and other start-up companies developing ISO accredited local biotech manufacturing.

The outcomes of these partnerships align with the African Union and European Union's joint vision for Africa to locally produce 60% of its vaccine-related technologies by 2040. This focus on local production of healthcare solutions in Africa will be further supported by Manufacturing and Access to Vaccines, Medicines and Health Technologies (MAV+) funding, an initiative dedicated to tackling barriers to manufacturing and access to health products and technology, with a focus on strengthening vaccine manufacturing and innovation, across Africa.

What’s next for the Stellenbosch Biofoundry

Looking ahead, The Stellenbosch Biofoundry plans to expand its equipment and operational capacity, enabling the facility to provide affordable and reliable support to the innovation pipeline. The researchers at this biofoundry plan to integrate AI into the design stage of the model, incorporating machine learning for predictive metabolic modelling. An important step in validating these models will be through demonstrating aligned results with experimental lab investigation. Additionally, the Stellenbosch Biofoundry will continue to focus on the learn phase of the model, which will enable more efficient innovation by using insights from testing to improve future design and build efforts. This will contribute to accelerating technology development, reducing time and resource utilisation thereby growing a sustainable biotechnology ecosystem in South Africa.

Committed to driving biotechnology innovation in Africa and beyond, the establishment of facilities, such as the Stellenbosch Biofoundry, will play a crucial role in supporting South Africa’s bioeconomy emphasizing the country’s position as a leading synthetic biology hub. Dr Trollope concluded, “By establishing the Stellenbosch Biofoundry, we are closing a key infrastructure gap and accelerating biotechnology innovation in South Africa and beyond.”

*The contents of the publication are the sole responsibility of Stellenbosch University and do not necessarily reflect the views of the EU or the Federal Ministry of Economic Cooperation and Development (BMZ).