Nuclear magnetic resonance (NMR) spectroscopy is becoming increasingly popular for high throughput applications, including compound library QC testing, protein-ligand screening and, more recently, screening of biological fluids for clinical research. Serving this diverse market poses a challenge to NMR instrument manufacturers such as Bruker BioSpin, requiring the development of modular and flexible automated sample preparation platforms to ensure optimal results.

Bruker BioSpin – part of the Bruker Corporation – is the leading global supplier of NMR technologies for research applications. Sixty years since the development of its first NMR spectrometer, the company’s systems are now relied on by researchers across the biomedicine, pharmaceutical development, clinical research, process chemistry and food safety sectors. Reproducible pre-analytical sample preparation is essential for many of these applications, making automation of these processes highly desirable to allow larger studies and ensuring more consistent and reliable results. Dr Ulrich Braumann, Group Leader and Product Manager for NMR Hyphenation at Bruker BioSpin, explained: “Around 10 to 15 years ago, we started looking for an automated sample preparation solution to complete our NMR package, as this element of the workflow is quite demanding. Our NMR systems are used for a wide variety of applications, so we needed a robotic platform that was modular and flexible, and could be extended to incorporate further applications in the future. We identified the Xantus® platform from Sias (now Tecan) as the best solution, and our long-term collaboration has led to the development of the SamplePro family of instruments. These systems are now our standard sample preparation offerings for NMR spectroscopy and combined NMR/LC-MS systems, with a choice of five systems to suit different liquid and solid sample types.”

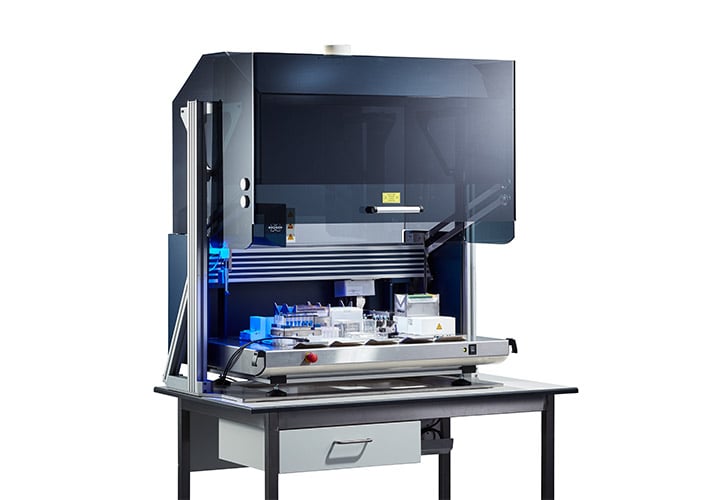

Automation of pre-analytical sample handling helps to ensure accurate and reliable NMR results

Automation of pre-analytical sample handling helps to ensure accurate and reliable NMR results

“One of the main requirements for sample preparation is the transfer and mixing of samples directly in the long, thin glass tubes commonly used in NMR workflows. The standard tube size is around 18 cm long and 5 mm in diameter, but they can be as small as 100 mm long with an internal diameter of just 0.8 mm for certain applications,” Ulrich continued. “To avoid a detrimental effect on NMR resolution, all liquid transfers – especially adding and mixing internal standards or solvents – need to be performed without creating air bubbles, foam or concentration gradients. Automation of these liquid handling steps with the SamplePro Tube platform enables precise and accurate results, while minimizing the need for user intervention. This is particularly important for customers in the pharmaceutical and clinical research markets, where viscous plasma samples are common, and pose additional biosecurity risks. This is also a good example of how our partnership with Tecan benefits customers. The SamplePro Tube uses a custom-developed, patented ‘downholder’ and centering system which both secures the glass NMR tubes in place and guides the piercing needles – which may be only 0.5 mm wide – into the tube caps to avoiding needle damage and liquid spillage.” “A big advantage of the Xantus instrument for us is that everything is modular and flexible. It is available in different deck sizes to suit various applications and throughputs, and can incorporate a wide range of standard modules for shaking, heating and vacuum extraction, as well as gripper arms for manipulating the different sample tray types. Many of our systems also have a Peltier cooling device, which was developed specifically for us. All the labware and devices that are placed on the workdeck are barcoded, and the robot uses an arm-mounted barcode reader to identify exactly what’s on the platform. This flexibility has allowed us to develop a barcode-oriented software control strategy, so the system always knows the identity and geometry of all the containers on the workdeck. For example, if you set up the system for 96 samples, you can open the door halfway through and change the position of the sample plate or tube rack, as the system is set up to pipette from a barcode-labeled microplate well into a barcode-labeled NMR tube, not from position X to position Y. The robot knows where to restart, and continues from the correct position, avoiding sample mix-ups.”

SamplePro’s barcode-oriented workflow allows a variety of NMR labware formats to be accommodated

SamplePro’s barcode-oriented workflow allows a variety of NMR labware formats to be accommodated

Ulrich continued: “Using Tecan’s development kit, we have been able to create a comprehensive software solution that can control the Xantus and communicate with our NMR systems, allowing the creation of the SamplePro LAB2NMR – a fully integrated, walkaway system that prepares samples and sends them directly to the NMR spectrometer. This system has a second robotic arm with a gripper tool to transfer the samples, and features extra shielding to protect the sample preparation platform from the NMR’s magnetic field. Our relationship with Sias, and now Tecan, has been very important in allowing us to provide this level of integration and flexibility to our customers. Most of our installations are for quite specialized applications so modularity and customization support – as well as quality – were key in choosing an automation partner,” Ulrich concluded.

Most of our installations are for quite specialized applications so modularity and customization support – as well as quality – were key in choosing an automation partner.

To find out more about Tecan Partnering and Tecan Synergence, visit www.tecan.com/OEM-products

To learn more about Bruker BioSpin’s automated NMR solutions, go to www.bruker.com/products/mr/nmr/automation

Keywords: