By Mellisa Enriquez

Cavro ADP Detect: an overview

Tecan's design engineering plays a crucial role in driving the automation of molecular diagnostics workflows. The Tecan® ADP pipettor range has a proven track record of successful integration into molecular diagnostics platforms worldwide. In our previous article, we highlighted how Cavro ADP pipettors bring a so-called “sixth sense” to automated pipetting. Here, we explore in more depth how the engineering behind the ADP Detect brings simplicity and accuracy to the automation of molecular diagnostics workflows.

Automated pipetting using Cavro® ADP Detect ensures enhanced process accuracy for molecular diagnostics research applications

In our first article in this series, we explained how adding the ADP Detect can make the life of the instrument developer easier. This is facilitated by the fact that Cavro OEM pumps and devices already conform to the requirements of ISO13485, ISO9001, and FDA 21 CFR Part 820 standards. Using components compliant with medical device manufacturing processes in your instrument design reduces risk and expedites regulatory approval, accelerating time-to-market for molecular diagnostic devices.

The ADP Detect is designed to be low-maintenance and is factory-calibrated for precise pipetting performance with a drive mechanism life expectancy of over five million cycles, ensuring uninterrupted and trouble-free operation.

ADP Detect: discover what’s inside

We now invite you to join us on a tour behind the scenes of the Cavro ADP Detect for a preview of the algorithm and detection capabilities that allow the speedy and precise automation of molecular diagnostic assays. This will help you better understand how to use the ADP Detect with increasing process security for your molecular diagnostics instrument, giving it enhanced sample and workflow traceability and actionable error detection.

Increased process security with the ADP Detect

The ADP Detect has the following key features that provide increased process security:

- Detection algorithm

- 3 types of liquid level detection

- Capacitive Liquid Level Detection (cLLD)

- Pressure-based Liquid Level Detection (pLLD)

- Hybrid Liquid Level Detection (hLLD)

- Tip process security (detects tip presence or ejection)

By using various combinations of these features, the ADP Detect magnifies the level of real time monitoring and detection of errors and anomalies in your instrument workflow, giving your diagnostic instrument the sensitivity, precision and speed that it needs.

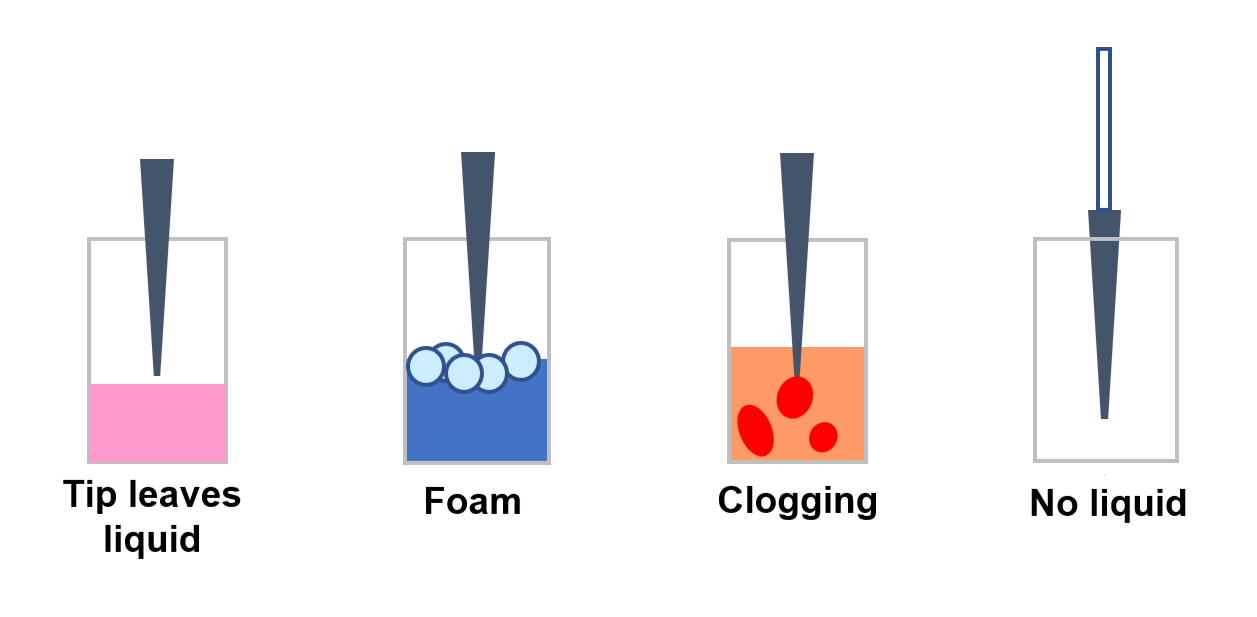

Some common pipetting errors that a molecular diagnostics instrument meets, and for which the ADP Detect can provide process monitoring and actionable error detection include: the pipette tip leaving the liquid, foam, clogging, and lack of liquid, as shown in Figure 1.

Fig. 1: Common pipetting conditions that are sources of process errors.

Aside from this, the ADP Detect can identify when the following events are happening in your molecular diagnostics instrument:

- Real time pressure data evaluation during aspiration

- Pressure streaming

- Liquid surface detection

- Other pipetting errors and anomalies such as:

- The tip starting and staying in the air during aspiration

- The tip leaving the liquid during aspiration

- The tip starting blocked and becoming unblocked

The ADP Detect: improving visibility

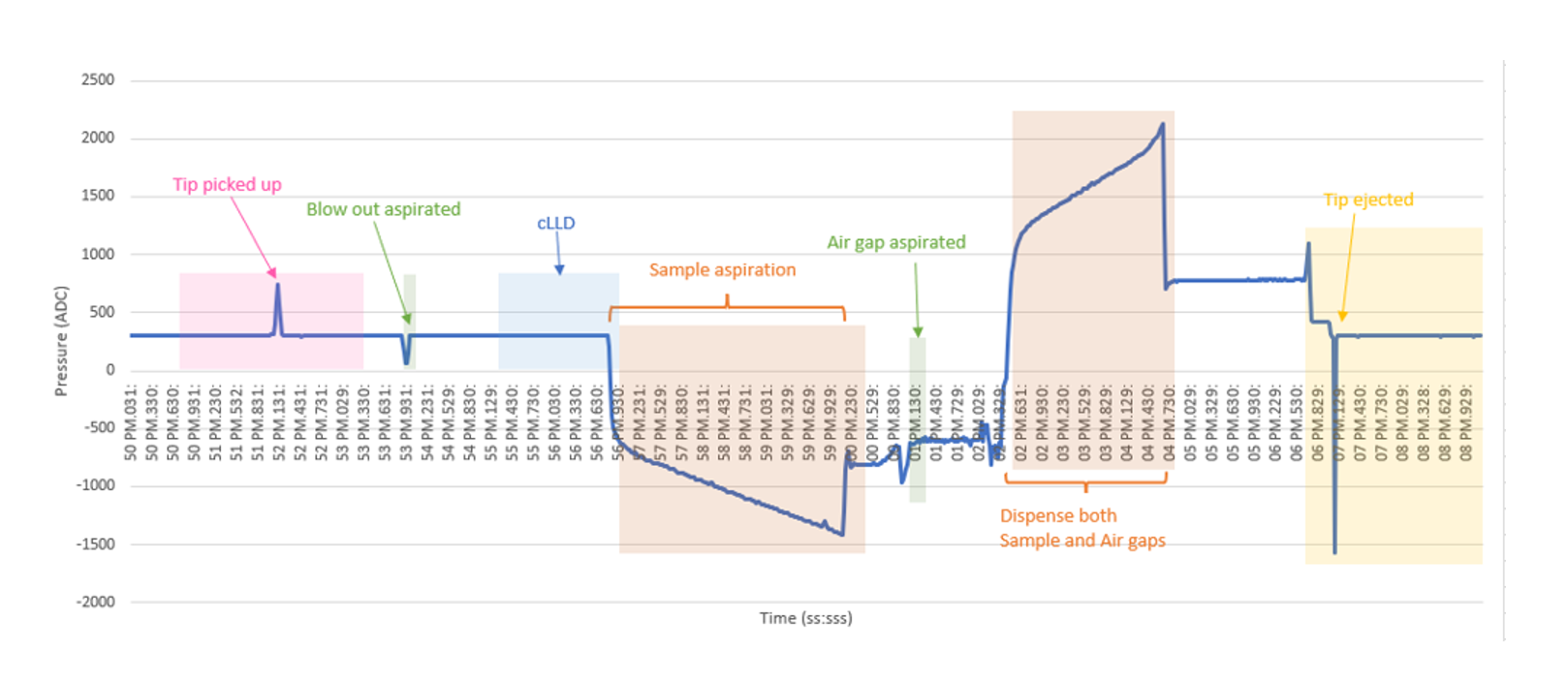

What does an ADP Detect pressure curve look like during a complete, normal aspiration and dispense cycle? Figure 2 shows how the ADP Detect gives you enhanced visibility of the variation in pressure during the entire cycle, so you can see exactly what is happening within your instrument during a molecular diagnostics assay run.

Fig. 2: Graphic showing normal ADP Detect curves generated during a complete aspiration and dispense cycle

To cLLD or not cLLD, that is the question

The ADP Detect has capacitive liquid level detection (cLLD) technology built in to enable accurate detection of the liquid surface. cLLD is based on the principle of electrical continuity of the sample and the cLLD circuitry and is used to detect the capacity change when a pipette tip contacts the conductive liquids.

However, depending on such variables as the sample, the type of liquid, and the desired outcome for the assay, one may have to use combinations of cLLD, pLLD (pressure-based liquid level detection) and hLLD (hybrid liquid level detection) for a given workflow.

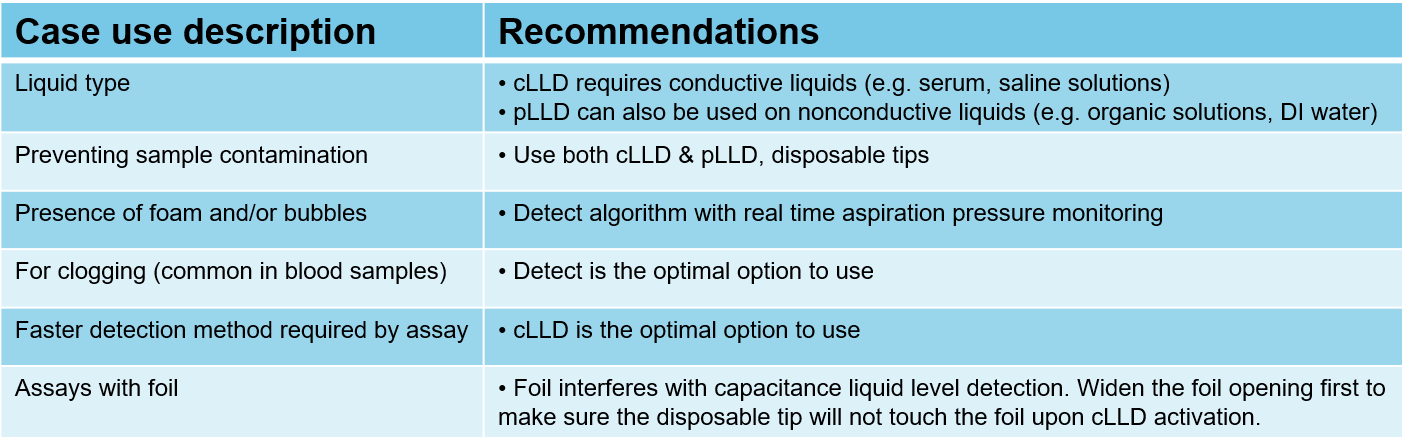

Table 1 outlines a few of the different scenarios that may be encountered, including the detection technology that may be the most suitable for a given sample or condition. This is also described in our white paper on using the Cavro ADP range in molecular diagnostics workflows.

Table 1: Choosing the right features for a specific situation or sample type.

A molecular diagnostics workflow will most often require a combination of detection methods, as demonstrated by this outline of the beginning of a typical workflow for serum samples.

Step 1

Serum sample transferred from patient collection test tube to a microplate. Serum is conductive and the tip needs to be located close to its surface, so cLLD is used for this transfer.

Step 2

Reagents and other fluids are then added, some of which are non-conductive, so pLLD must be used.

Step 3

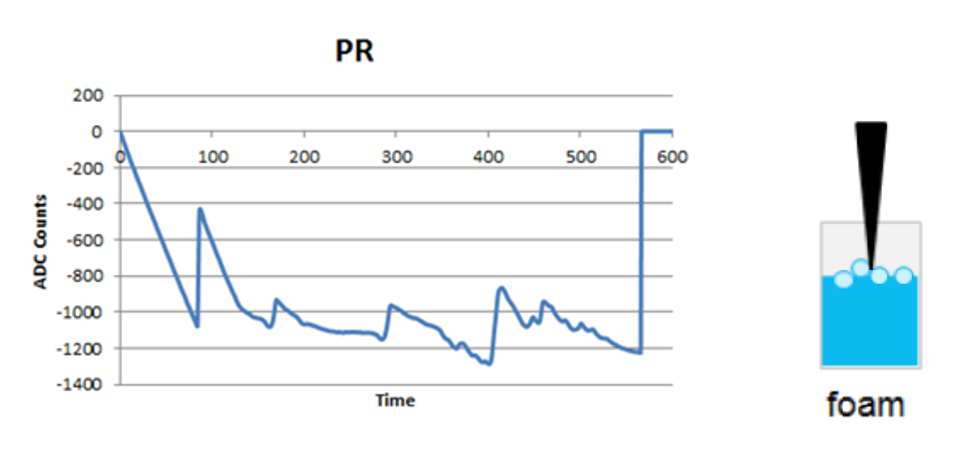

Reagent and sample mixing may generate bubbles or foam. The Detect algorithm and pLLD can then be used together. Their signals will alert the instrument arm that the tip is still in the foam, preventing premature aspiration. Once the tip is finally past the foam and in the liquid, aspiration will be initiated.

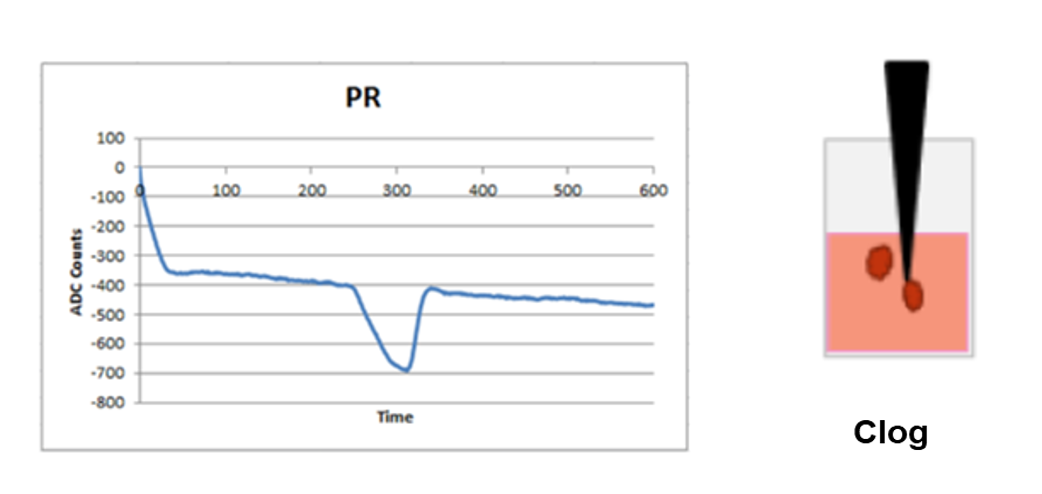

During the workflow, a tip may get clogged. The Detect algorithm alerts the system that there is a clog, and the instrument can either halt or divert to a suitable protocol.

The ADP Detect algorithm deep dive

The Detect algorithm is easy to use since it is completely contained within the pump firmware, so the user doesn’t need an external computer or software. There is only a single parameter, and its default setting will work with most applications. It works automatically, without the user needing to enter common aspiration parameters, such as the sample volume, plunger speed (preferably above 60 μl/sec), initial pressure reading, liquid viscosity or density, or tip characteristics such as volume, immersion depth, orifice size, or diameter. Data from the pressure sensor can also be streamed in real-time to enable other pressure monitoring tasks via a host computer, such as pipette blockage or foam detection.

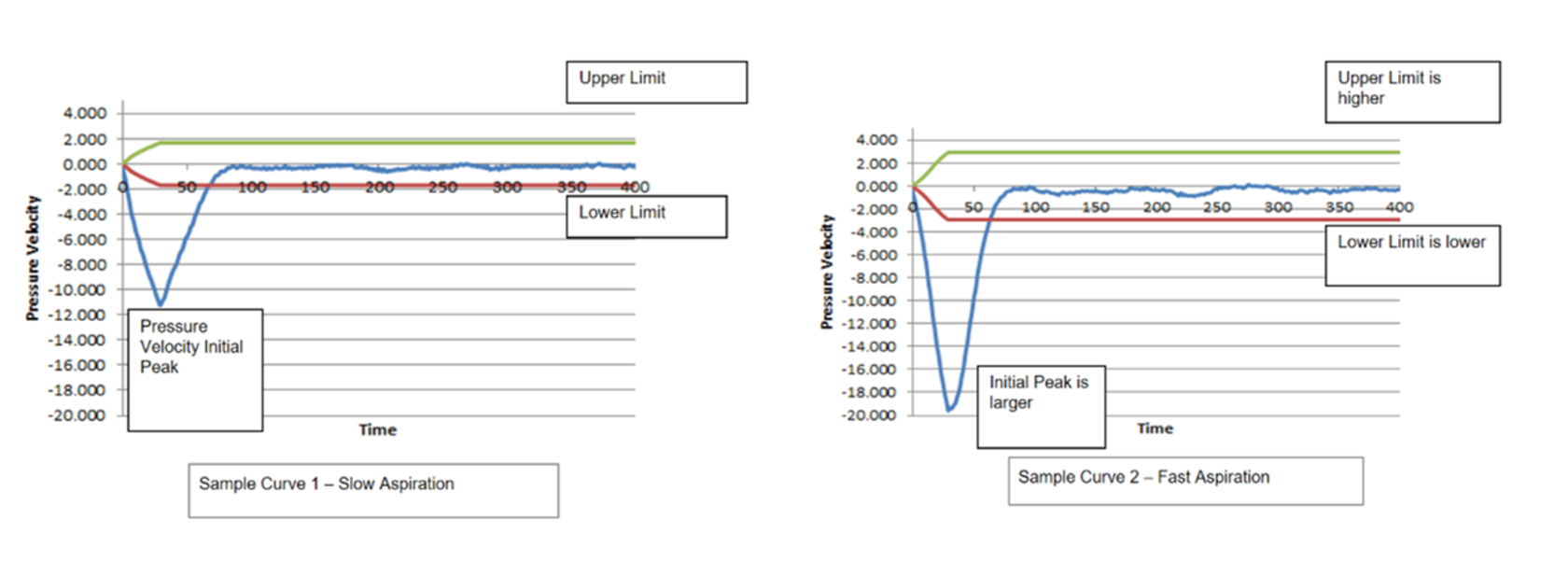

The algorithm uses the streaming pressure reading, the velocity of the pressure change, and the acceleration of the pressure change to determine if the aspiration is following an expected pattern or not. It monitors the velocity and acceleration of the pump and identifies whether they are positive or negative. As a result, it can determine the specific point on the pressure curve at which it is operating and apply different criteria to the acceleration and steady-state portions of the movement. It uses the magnitude of the initial pressure velocity to set limits for future velocity readings, making it insensitive to aspiration speed or liquid viscosity. This is represented graphically in Figure 3.

Fig. 3: The ADP Detect algorithm uses the magnitude of the initial pressure velocity to set limits for future velocity readings, making it insensitive to aspiration speed or liquid viscosity.

The Cavro ADP Detect can use a variety of conductive tips, so samples can be taken directly from standard blood draw tubes, which require longer tips of around 75 mm, as well as from standard microplates (96 or 384), and can be adapted for most custom labware. Let us now see how the ADP Detect pressure curve looks in different scenarios.

ADP Detect: situation normal!

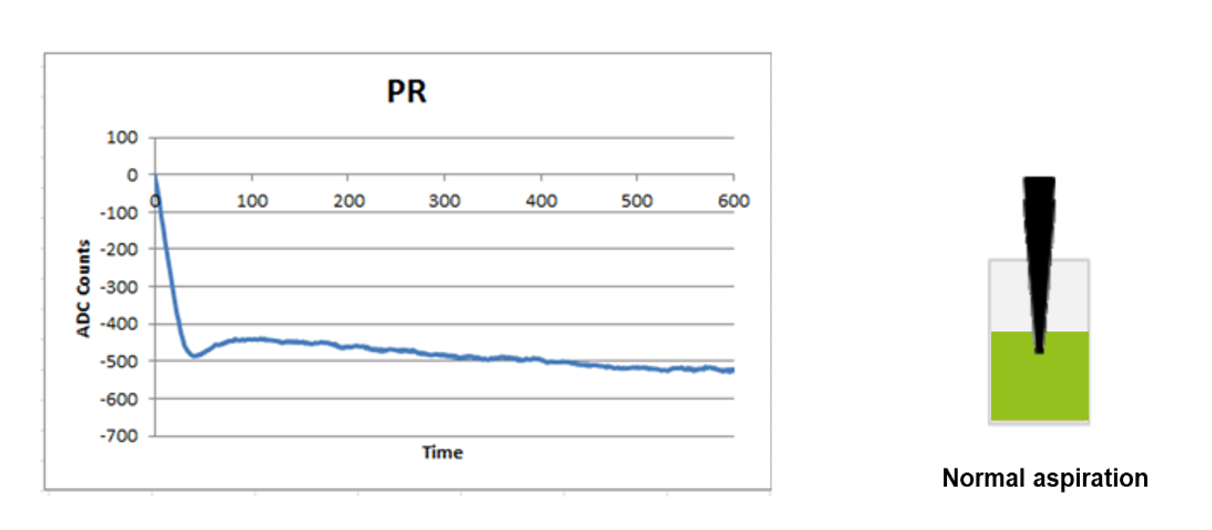

How does a “normal” aspiration look on a pressure curve, under standard pipetting conditions? Figure 4 shows the pressure curve generated using 150 μl of distilled water with a 200 μl tip, at an aspiration speed of 100 μl /sec.

Fig. 4: Change in operational pressure with time during a normal aspiration.

ADP Detect: clog alert!

When a clog occurs, the algorithm will detect the error in real time. When a clog event is detected, the ADP Detect can be instructed to stop, and your system can initiate a set of protocols to remove the clog and resume the aspiration cycle. This will help to conserve fluids and precious samples. Figure 5 shows what happens to the pressure curve when a tip becomes clogged.

Fig. 5: Pressure curve generated when a clogged pipette tip is detected by the ADP Detect algorithm. 100 μl of clogged liquid with 1000 μl tip @ 60 μl/sec.

ADP Detect: foam alert!

When there is foam present in the sample, as seen in Figure 6, an abnormal rise in pressure is seen by the ADP Detect, indicating an early exit of the tip from the liquid, or a tip becoming unclogged after having built up a large negative pressure.

Fig. 6: Pressure curve generated when foam in a blood sample is detected by the ADP Detect Mode algorithm. Blood foam sample, 200 μl tip @ 80 μl/sec.

Cavro ADP Detect simplifies and accelerates instrument design

Molecular diagnostics workflows require accurate and reliable liquid handling solutions capable of performing low-volume liquid transfers whilst eliminating the risk of sample contamination and carry-over. The use of OEM modules designed for medical devices, such as Cavro ADP Detect, dramatically reduces risk, simplifies regulatory approval, and speeds up time-to-market for molecular diagnostics devices. A final bonus is that the ADP Detect is scalable, so a system can use 1, 2, or 4 pipette modules in parallel, for example. This is ideal when starting with new diagnostics applications, and for situations where it may be useful to remove the human variability element. Talk to an expert today and find out how to optimize the integration of Cavro ADP Detect into your next instrument design.

About the author

Mellisa Enriquez

Mellisa is currently the Senior Product Marketing Manager for Tecan’s Cavro robotic and pipetting components. She has over five years of instrument and consumable product development and marketing experience. Her current focus is on developing new technologies for diagnostics and -omics instrumentation.