Tecan uses cookies to improve our website. By continuing to browse our website, you accept our cookie policy.

Tecan uses cookies to improve our website. By continuing to browse our website, you accept our cookie policy.

Keywords:

In vitro diagnostics (IVD) is central to the provision of healthcare globally, and is estimated to be worth in excess of $8.2 billion (€7.3 billion) a year in China alone.1 Despite this, the Chinese IVD landscape has historically been controlled by large international providers, with few domestic instrumentation and assay suppliers. Start-up company Shenzen AiTe is looking to change this, with the development of diagnostic platforms and assays offering rapid detection for a wide range of blood-based markers.

Blood-based testing is at the heart of pathology services, and accounts for a large proportion of the total diagnostic workload in almost every hospital lab and independent facility around the world. Shenzen AiTe is looking to break into the vast testing market in China by developing its own range of fully-automated IVD platforms. Peter Peng, CEO and founder of Shenzen AiTe, explained: “Blood-based diagnostics is a huge industry here in China but, at present, it is dominated by just a few big international companies, which have around 85 percent of the market. Over the last decade or so, Chinese companies and investors have become increasingly interested in this sector, looking to expand the proportion of the market controlled by domestic providers. This has had the ripple effect of more people studying the necessary biomedical and engineering disciplines at university, providing a rich pool of talent locally. I founded Shenzen AiTe to tap into this potential and develop a range of chemiluminescence-based diagnostic assays and instruments for hospital laboratories.”

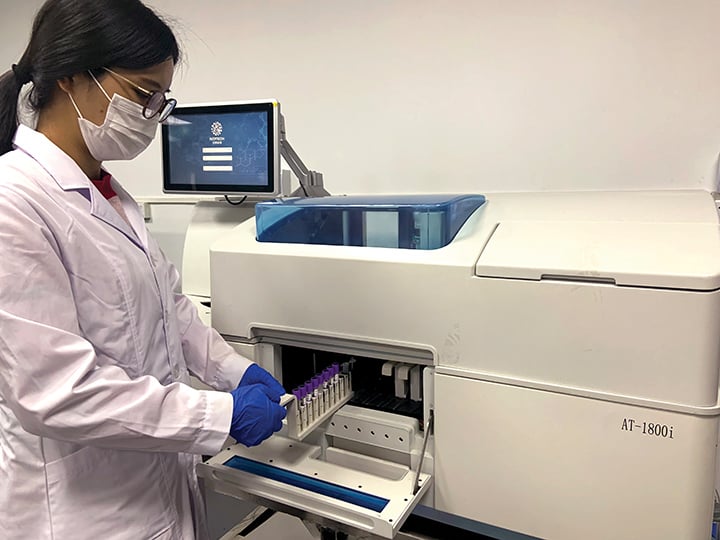

The systems fully automate the analytical workflow

“The basic principle of our instruments is to fully automate the entire analytical process; the operator simply loads the blood sample tube onto the platform. A built-in barcode reader then identifies the sample and, by connecting to the hospital or laboratory information system, determines which assays need to be performed. Parallel testing of all samples takes approximately 15 minutes using our proprietary chemiluminescence-based assay chemistries. We are developing two instruments – with capacities of 30 or 60 tubes – to cater for different sized laboratories, giving a maximum throughput of 180 tests per hour.”

“To perform each assay, the system transfers 5-50 μl of blood into a ‘cup’ containing the target-specific reagents. The reaction vessel is then incubated and washed several times, before being analyzed with a built-in luminescence reader. Since these tests could include infectious samples, we wanted to avoid the use of washable fixed tips for liquid handling, which increases the risk of cross-contamination. We therefore wanted a pipetting system that used disposable tips as, although this increases the cost slightly, it eliminates the contamination risk. Rather than design our own liquid handling module, we looked at the solutions already on the market that used disposable tips, and chose the Cavro® Air Displacement Pipettor (ADP) and Tecan disposable tips. This module provides advanced pipetting parameters to ensure accurate and reliable liquid transfers, even for complex fluids such as blood.”

“Integration of the Cavro ADP into our platform was easy, and we have had ongoing support from the Tecan Cavro team in California to ensure optimal pipetting performance. We have also chosen the Cavro Pulssar PBC Pump for distribution of our chemiluminescent reporter reagent, as we need to accurately dispense 5 μl of reagent into each reaction vessel to ensure reproducible quantitative results. This piston pump is very accurate and reliable, and has an ultra-low maintenance design, making it ideal for our needs.”

“Both components have been straightforward to integrate into our system design in terms of the hardware and the software, which has helped us to speed up instrument development. Although we are currently still in the development and validation phase, our aim is to achieve national certification for the instruments towards the end of 2020, and release the systems into the market in early 2021. Using validated liquid handling components with certified performance will certainly help with this process, and we are very happy with our choice of Tecan Cavro components,” Peter concluded.

1) www.prnewswire.com/news-releases/china-in-vitro-diagnostic-ivd-industry-report-2019-2025-300880671.html

This module provides advanced pipetting parameters to ensure accurate and reliable liquid transfers, even for complex fluids such as blood.

To find out more about Tecan Cavro components, visit partnering.tecan.com/cavro

Keywords: