Keywords:

Microbioreactors are a convenient research tool, enabling cost-effective screening of a variety of fermentation parameters prior to scale-up and manufacturing of biological products. m2p-labs’ proprietary bioreactor technology offers automated, parallel monitoring of multiple micro-fermentations, and has been proven in applications such as clone screening, media optimization and synthetic biology.

m2p-labs, formed at the end of 2005 as a spin-off from RWTH Aachen University, is a leading international supplier of microbioreactor systems for fermentation, screening and bioprocess development. Octavia Deufel, Marketing and Communications Manager at m2p-labs, explained: “Our products are mainly used for R&D applications, particularly in the chemical, biotechnology and pharmaceutical sectors. We also have a number of customers in the cosmetics industry and, of course, we supply equipment to a lot of academic labs. Our original benchtop system – the BioLector® I – was designed to allow high throughput micro-fermentation experiments, with real-time monitoring of important parameters, such as biomass, pH value, oxygen saturation and fluorescence. The ability to optically measure biomass is unique to our reactors, and this is extremely important for microbial applications. Most pertinent data for fermentations is, in some way, connected to biomass, and the BioLector offers the capacity to do this non-invasively.”

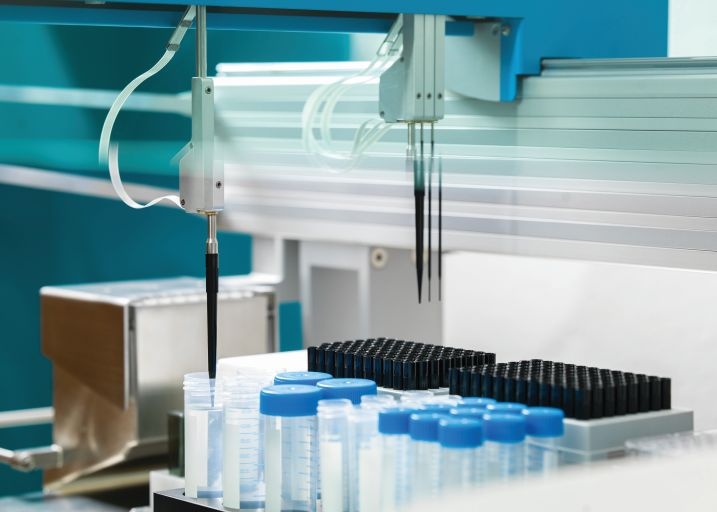

Product Manager Sebastian Hofzumahaus added: “We have since expanded the range with a number of additional features and options, but all of our systems are capable of doing 48-well plate fermentation – effectively 48 parallel microbioreactors – and measuring these key fermentation parameters. The difference between the models is the level of automation they provide. The RoboLector® is therefore the natural extension of the BioLector range, enabling full bioprocess control – making pH adjustments, adding inducers and feed solutions, etc. – based on the real-time data or a pre-programmed schedule, or a combination of both.”

“We began the RoboLector project in 2009,” commented Sebastian Blum, European Sales Director. “We started by speaking to customers, to get an idea of what they wanted from a fully automated system. We already knew that we wanted to go from batch fermentations to fed-batch fermentations, as well as offering automatic sampling and adjustments, but it became clear that users want a very flexible system capable of fitting seamlessly into their workflows. We therefore looked for an OEM robotics supplier that could provide a modular liquid handling option that would be easy to integrate with our BioLector systems. The Xantus® was the only solution on the market with the level of flexibility we wanted to offer to end users – it was a perfect fit.”

The development of the RoboLector proceeded quickly. In just nine months, m2p-labs moved from initial planning to shipping the first systems to customers. Sebastian Hofzumahaus described the process: “Most of the Xantus hardware could be used off-the-shelf, but we required a number of small modifications to simplify integration, such as an extended X-axis to enable full access to the BioLector system. These adjustments were undertaken quickly and efficiently, and we are now able to offer customers a choice of three options depending on their throughput. The basic model has two pipetting channels, one with a washable fixed tip, and the other using disposable tips. We then offer a four-channel version – again with a single channel using disposable tips – and an eight-channel model, using two channels with disposables tips for maximum throughput.”

"Users want a very flexible system capable of fitting seamlessly into their workflows."

“The software programming was done almost entirely by us in house, with a little bit of help and support from the Sias software development team,” Sebastian continued. “An important consideration, which influenced our initial decision to choose the Xantus, was the availability of a number of standard software drivers and interfaces. This was a huge benefit, and the support we received during development was great. A number of our service technicians and application specialists have also been on Tecan’s training courses, allowing us to take on most customer service and technical support by ourselves. We have a really good relationship with the Tecan team as well and, if we encounter a new problem that we don’t really know how to solve immediately, we can always get really quick and very solid support from Tecan’s personnel and the expert helpline.”

“We are continually honing our software and modules to meet our customers’ evolving needs. This year, for example, we have developed a new pre-culture module for the RoboLector. This allows us to reliably induce all 48 fermentations with the same quantity of cells, further reducing hands-on time and greatly increasing reproducibility. This module was suggested to us by a customer who had recently purchased a RoboLector platform, and we were able to work together with them to develop this option in just a few weeks. It’s a testament to the flexibility of the Xantus robot that we were able to so easily integrate this new module into our existing automated platform,” Sebastian Blum concluded.

For research use only. Not for use in clinical diagnostics.

To find out more partnering with Tecan, visit partnering.tecan.com

To learn more about m2p-labs and the RoboLector, go to www.m2p-labs.com

Keywords: