GAP Peptides has developed a novel approach to synthesizing high crude purity peptides that minimizes solvent and raw material consumption, while simultaneously reducing waste. Laboratory automation is helping this start-up company to accelerate its research and development, a process crucial to achieving commercial success. The company founders have collaborated with Tecan to establish a unique liquid handling platform, designed and built specifically to meet its workflow needs.

Scientific interest in peptides has expanded exponentially over the past decade, and today these biomolecules are ubiquitous across a range of sectors. The marketing potential is huge. In the therapeutic sector alone, a compound annual growth rate in excess of 10 % – in the region of 25 to 40 billion dollars – is projected over the next few years. The complexity of synthesizing these peptides presents a challenge for manufacturers, who must achieve high purity in a cost-effective manner and, at the same time, adopt more environmentally friendly processes.

GAP Peptides, based in Lubbock, Texas, has developed an innovative process that addresses these issues, helping manufacturers to bring new synthetic peptides to market at an affordable price point. When performed manually, simultaneous synthesis of the multiple peptides needed for research can be very time consuming, so the company has automated the process on a

Fluent® 1080 Automation Workstation. CEO and Managing Director Caroline Brooks explained: “Our work is based on a novel synthesis strategy, Group Assisted Purification-Peptide Synthesis (GAP-PS), developed by our CSO Dr Cole Seifert and his research adviser, Dr Guigen Li, during his PhD studies at Texas Tech University. This unique synthesis approach will help manufacturers to improve yields, reduce the consumption of raw materials and minimize solvent waste, producing peptides faster and with higher purity compared to other methods.”

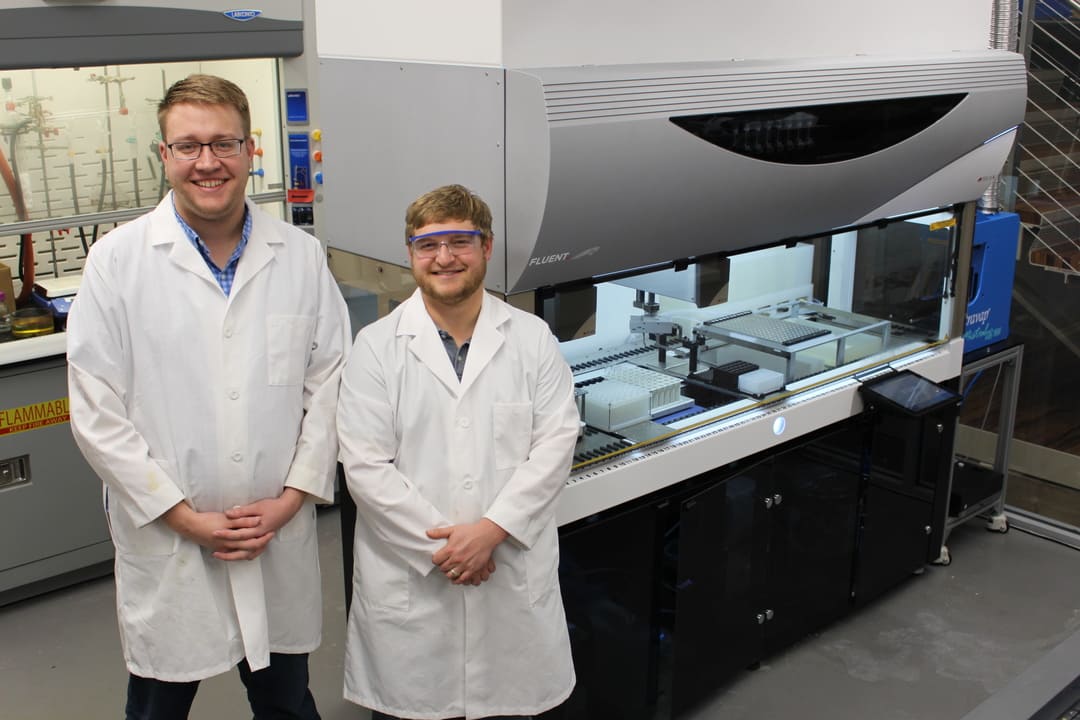

Cole Seifert (left) and Carder Brooks co-founded GAP Peptides in 2017

Cole Seifert (left) and Carder Brooks co-founded GAP Peptides in 2017

Cole took up the story: “Traditional solid phase peptide synthesis is performed on a polymer support. However, the peptide never actually dissolves in the reaction solvent, and that means that the synthesis is often not very efficient, resulting in lower purity. The process also uses a large volume of solvent to swell and suspend the resin, requiring a larger reactor and increasing the amount of solvent waste generated. With GAP-PS, we attach a specifically designed small molecule protecting group to the C-terminus of the first amino acid, which ensures solubility in the reaction solvent; with everything in solution, we can use a smaller reactor and reduce solvent waste. The synthesized peptide is isolated by selective precipitation after an aqueous extraction step, offering a simple purification process to match that of solid phase techniques. This allows us to keep the benefits of solid phase synthesis while increasing the reaction efficiency – which enhances the peptide purity – and the scalability of the process.”

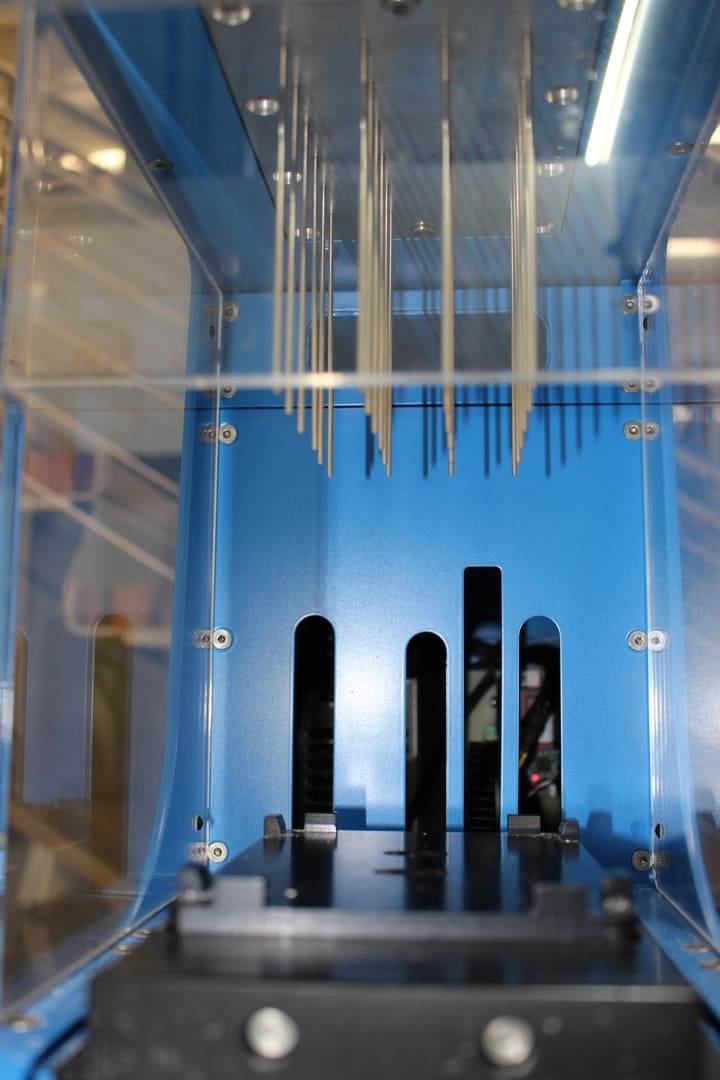

Fixed steel tips provide reliable septa piercing

To enable commercial adoption of its GAP-PS technology, the company needs to provide substantial data demonstrating the purity, yield, length and complexity of the peptides produced. Implementation of a fully automated liquid handling system is the key to achieving this, and GAP chose a Fluent 1080 to increase throughput, enabling reliable, consistent data to be generated more rapidly. Tecan tailored the system to the company’s workflow, integrating a SciRobotics TubeEyeX™, a ppSPE device, an IKA shaker and a Porvair sample concentrator – the first time this has been done on a Fluent workstation. Partnering with Tecan was an obvious choice for Caroline: “Tecan is well known in the life sciences arena for its experience and in-depth knowledge of chemistry and automation, and we very quickly discovered the company’s expertise in designing and planning a customized instrument to meet our needs. This expert insight made it stand out and gave us the confidence to choose Tecan.”

The Fluent Automation Workstation has been customized for GAP-PS peptide synthesis

The Fluent Automation Workstation has been customized for GAP-PS peptide synthesis

A single person working manually could synthesize one, maybe two, 10-amino acid peptides in about a week. In contrast, the Fluent can generate 24 peptides, completing the process in about three days.

Carder Brooks, General Counsel at GAP, added: “Tecan’s experience in developing customized platforms and integrating third-party devices into the hardware and software played a major part in our choice of system. We explained that we needed a custom-designed workstation to automate a novel peptide synthesis. While others said it could not be achieved, Tecan’s response was that, although it had never done anything like this before, it had all the components necessary and was confident that it could assemble and program a platform to meet our needs, supporting us all the way from design to implementation.”

“The beauty of the Fluent is that it enables us to show the capabilities of our technology in a way that would be impractical without an automated liquid handling platform,” said Caroline. “It gives us a tremendous capacity that we just wouldn’t have if we did our research manually, enabling the synthesis of as many as 24 peptides at any time. This allows us to go to market with all the proof necessary to gain credibility, giving potential customers confidence that our technology works. Without an automated liquid handling system, this would be a very slow and painful process.”

Blue food coloring is used to allow the TubeEyeX to distinguish between the layers during the aqueous extraction step

Blue food coloring is used to allow the TubeEyeX to distinguish between the layers during the aqueous extraction step

Cole expanded on the time savings offered by automation: “A single person working manually could synthesize one, maybe two, 10-amino acid peptides in about a week. In contrast, the Fluent can generate 24 peptides, completing the process in about three days, which makes a huge difference to our throughput.”

“Peptide chemistry is very complex, as is the integration of all the third-party modules into the Tecan operating software, but the company has managed to create a user-friendly interface that simplifies the workflow, allowing us to make changes to meet our specific needs relatively quickly and easily. It’s been a good collaboration,” concluded Caroline.

To find out more about Tecan’s Fluent Automation Workstation, visit www.tecan.com/fluent

To learn more about GAP Peptides, go to www.gappeptides.com