Tecan uses cookies to improve our website. By continuing to browse our website, you accept our cookie policy.

Tecan uses cookies to improve our website. By continuing to browse our website, you accept our cookie policy.

Precise liquid handling is critical to both research and routine analysis in a laboratory environment, requiring accurate transfer of samples, reagents and buffers from one container to another to ensure consistent results. For applications such as chromatography and spectrometry, it is just as important to be able to achieve a reliable continuous flow of fluids over a prolonged period. DURATEC has been supplying modules, accessories and consumables to analytical laboratory, life sciences research and process engineering markets for over 25 years, and offers a number of precision pumping and dispensing devices for integration into laboratory set-ups for various applications.

Continuous fluid flow is essential for a variety of activities in the laboratory, from bulk dispensing of buffers and cell culture media to chromatography. For basic dispensing applications, impellers or peristaltic pumps are often sufficient, but these rarely achieve the accuracy, consistency or control necessary to perform sensitive analytical techniques, such as LC-MS. Instead, these applications rely on coordinating the actions of two or more automated liquid handling devices – such as syringe pumps – to achieve a continuous fluid stream. This approach requires careful design of the fluid path and precise switching between pumps to achieve consistent fluid flow, with coordinated acceleration and deceleration to avoid flow disruption and pressure spikes.

DURATEC Analysentechnik GmbH, based in Hockenheim, Germany, is a specialist manufacturer and supplier of modules and devices for the chromatography, spectroscopy and process engineering sectors. The company’s diverse product range is intended to suit numerous applications, as Managing Director Dr Gerald Degenhardt explained: “We offer a wide range of bolt-on modules and standalone devices to suit sample preparation, analytical and post-processing activities across several markets. Some of our customers want a complete solution to suit their application, whereas others simply want a single module to integrate into their workflow. A majority of our customers are in the pharmaceutical and chemistry sectors, but we also have strong ties to the biotechnology, medical diagnostics and semiconductor industries. We therefore aim to develop devices with broad applicability across sectors, without the need to create bespoke solutions for every market.”

Duratec’s modular solutions are used across a range of analytical, life sciences and process engineering applications

Duratec’s modular solutions are used across a range of analytical, life sciences and process engineering applications

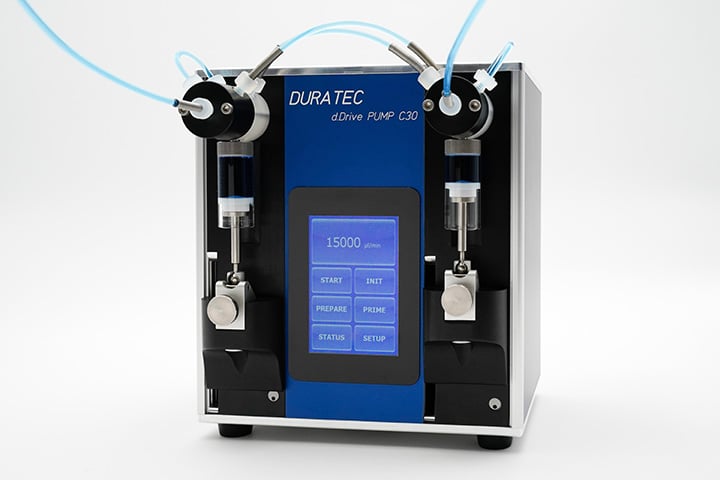

DURATEC’s portfolio includes a number of flexible continuous flow devices based on syringe pump technologies, offering flow rates from 1 μl/min to 300 ml/min. Gerald continued: “Pumping and dosing are common activities in sample analysis and process engineering, and we have offered syringe-based high precision drive pumps for many years. In 2018, we were looking for a new OEM syringe pump to replace the existing unit used in our d.Drive PUMPs, which was being discontinued by the manufacturer. We investigated the various options on the market, and found Tecan Cavro® OEM components to be the best match for our technical requirements, offering the high levels of accuracy and control we required.”

This allows us to cover a very broad range of flow rates without having to change the instrument design or compromise precision.

“We currently offer two d.Drive PUMP models featuring Tecan Cavro syringe pumps – the C30 and X60 – depending on the customer’s application requirements. The C30 is intended for lower flow rate applications and features two Cavro Centris Pumps, while the larger X60 model uses two Cavro XLP 6000 Pumps for higher flow rate applications. Although the stroke lengths of these syringe drives is fixed – 30 mm and 60 mm respectively – Tecan offers a range of syringe sizes for each pump. This allows us to cover a very broad range of flow rates without having to change the instrument design or compromise precision. Both pumps are robust and very accurate, and operate across a wide range of pressures to match our customers’ needs.”

“We first adopted the Tecan Cavro components in 2018, and they proved easy to integrate from both a hardware and software perspective. One of our key considerations when selecting these pumps was the ability to achieve a smooth transition from one syringe to the other, to minimize pressure and flow fluctuations, as well as pulsing. The pump firmware makes it easy to achieve this seamless choreography through our own software – coordinating the acceleration of one syringe with the deceleration of the other – as well as enabling flow rates to be adjusted on the fly. The ability to control both syringe pumps via an external computer or an onboard microcontroller also gives our customers greater flexibility in their system design,” Gerald concluded.

To find out more about Tecan Cavro OEM components, visit partnering.tecan.com/cavro

To learn more about DURATEC Analysentechnik, go to www.duratec.info