Tecan uses cookies to improve our website. By continuing to browse our website, you accept our cookie policy.

Tecan uses cookies to improve our website. By continuing to browse our website, you accept our cookie policy.

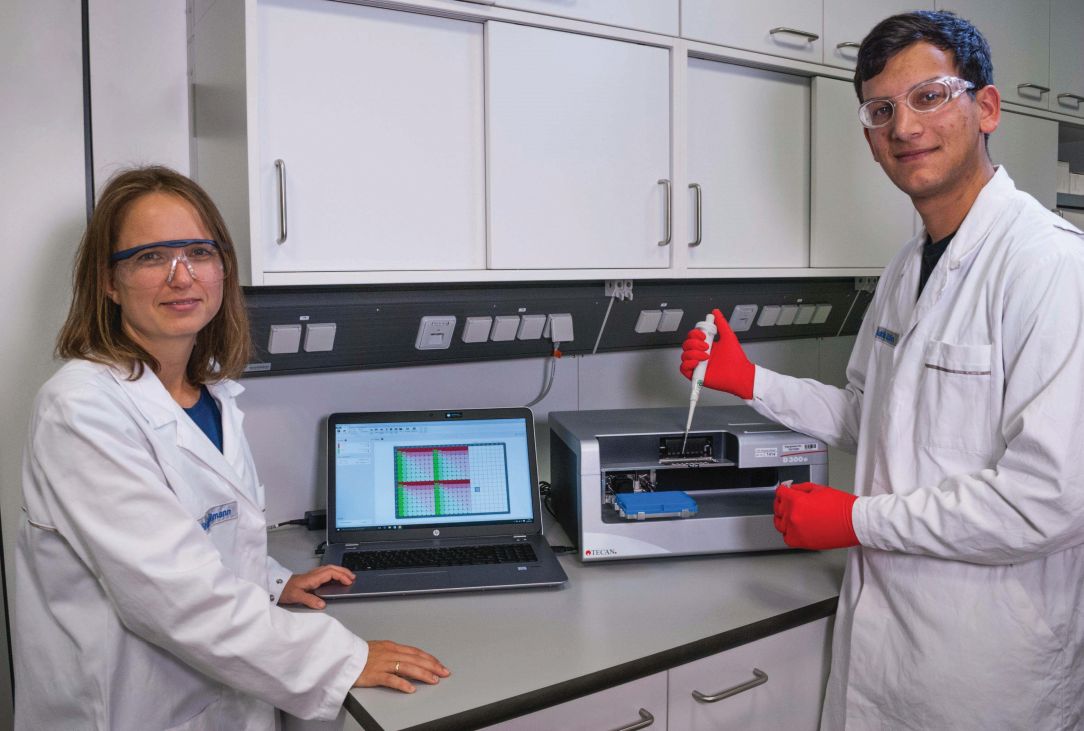

Automation brings more than simply speed to the laboratory. Modern software is taking the headache out of serial dilution and normalization calculations, supporting assay development and delivering reliable results for international healthcare company Merck.

Merck KGaA is a global science and technology company working in the healthcare, life sciences and performance materials sectors. The company – which celebrates its 350th anniversary in 2018 – operates in over 65 countries with approximately 50,000 employees. This year, Merck received FDA approval for its immune checkpoint inhibitor, BAVENCIO® (avelumab), used to treat metastatic Merkel cell carcinoma, a rare and aggressive skin cancer. Dr Nina Grossmann, a laboratory head within the discovery pharmacology department in Darmstadt, Germany, explained: “Our department is primarily focused on small molecule drug discovery, split across two sub-departments: cellular and molecular pharmacology. We handle all kinds of biochemical assays, which we miniaturize for high throughput screening and mode of action studies.”

“My lab is currently working on a number of projects in the areas of oncology and immuno-oncology, developing assays for different targets, such as specific protein-protein interactions and protein kinase assays. In March 2017, we developed an homogeneous time- resolved fluorescence (HTRF®) assay for protein-protein interaction studies, and we wanted to purchase an instrument to support our assay development and manage the large number of enzyme and antibody titrations. We looked at the various dispensers on the market before deciding on the Tecan D300e Digital Dispenser. We really appreciated the instrument’s ability to work across a broad volume range – from picoliters to microliters – as there are not many dispensers that can do this. We also use the instrument to support regular compound titration testing.”

"The main benefits of the D300e have been the increased accuracy and time savings… we probably save ourselves one day per run."

“The main benefits of the D300e have been the increased accuracy and time savings; assay development is now much faster. We really appreciate the reduction in preparation time, which people often overlook. We simply set up the metrics on the instrument – such as the titrations we want to carry out – and the system does the rest, calculating everything, including the normalization. If we were to do this by hand, we would have to create different stock solutions of the buffers, and we simply don’t have to do this anymore. Preparing a plate only takes about half an hour on the D300e whereas, previously, doing the calculations and pipetting by hand took a long time. We also had to use a series of titrations to narrow down the concentration range for further investigation. The D300e allows us to carry out these multiple steps in one experiment, and we probably save ourselves one day per run. In addition, the error rate is now much smaller, and the data is more reliable.”

“We use 384-well plates for our assay development and, even though our technicians are very experienced with this format, the error rate of the Tecan system is still much lower. The D300e also helps us prepare for high throughput screening using 1,536-well plates – which we simply could not pipette by hand – saving us valuable reagents.”

“Whenever we have contacted Tecan support with questions, we get the answers we need quickly. For example, we’ve had some queries about using the software and about which detergents were most suitable for use with the digital dispenser. We also had a concern that using automation may damage or destroy the protein in some way, but we are currently using the D300e in five different projects and have not encountered any problems,” Nina concluded.

To find out more about Tecan’s D300e Digital Dispenser, visit www.tecan.com/D300e

To learn more about Merck, go to www.merckgroup.com