Tecan uses cookies to improve our website. By continuing to browse our website, you accept our cookie policy.

Tecan uses cookies to improve our website. By continuing to browse our website, you accept our cookie policy.

Spanish company Advanced Wave Sensors (AWSensors) is playing a key role in the pan-European Horizon 2020 LiqBiopSens and Catch-U-DNA projects to develop a new liquid biopsy platform for the early detection of colorectal and lung cancers. An important part of this process was the creation of a liquid handling platform incorporating an acoustic wave sensor array and microfluidic technology for the analysis of biomarkers in blood.

Colorectal cancer is the third most common cancer worldwide according to World Cancer Research Fund data, making it an important diagnostic target. Currently, tissue biopsy is the conventional cancer identification technique. However, this is an invasive procedure that only delivers a snapshot of the patient’s condition at a specific moment in time. An alternative method is the use of liquid biopsies, where biomarkers are monitored in body fluids, such as blood, saliva and urine. Liquid biopsy is a far less invasive process than tissue biopsy and, crucially, allows tumor dynamics to be monitored in real time. The Horizon 2020 LiqBiopSens and Catch-U-DNA projects aim to replace the labor-intensive, costly and occasionally biased PCR-based approach currently used for the detection of genetic markers with a liquid biopsy platform that uses acoustic wave sensing to deliver precise, real-time and robust DNA quantification.

AWSensors was spun out from the Polytechnic University of Valencia a decade ago, building on years of research in the field of piezoelectrics to produce acoustic sensors and complementary electronic instrumentation. The company’s focus is on high frequency, quartz crystal microbalance with dissipation measurement (QCMD) sensors and sensor arrays – as well as control electronics and software – and microfluidics to allow miniaturization of the systems and sample volumes for specific analyte detection. Maribel Rocha, an application scientist at AWSensors, explained: “Our company was founded to make advanced QCMD-based technology available to the wider community, by developing and manufacturing high precision sensing instrumentation for basic and preclinical research and industrial applications. This technology has many potential applications, with biosensors proving to be one of the most important sectors.”

The AWSensors team

A particularly important use for this technology is the development of biosensors for the detection of cancer biomarkers, and AWSensors is working with its Horizon 2020 partners across Europe to develop a novel early detection system. Maribel continued: “As part of the LiqBiopSens and Catch-U-DNA projects, we are developing a reliable, rapid, non-invasive liquid biopsy assay to detect colon and lung cancer. The aim is to combine our ultrasensitive acoustic wave sensors, microfluidic cartridge technology and engineering capabilities with novel chemical reagents from DestiNA Genomics, creating an automated platform for the analysis of liquid biopsies for circulating tumor DNA. To do this, we needed to develop a liquid handling platform that could accommodate a microfluidic device and a 24-sensor array for simultaneous monitoring of multiple biomarkers.”

AWSensors looked at the different options available on the market, and chose the Cavro® Omni Flex robot, equipped with a Cavro XMP 6000 Pump and Cavro Air Displacement Pipettor (ADP). “After talking to Tecan, we chose the Omni Flex, as Cavro is a brand that offers good value and high quality. We also knew that, as a complete liquid handling system, the Cavro Omni Flex would significantly reduce the time taken to develop the liquid biopsy platform,” said Maribel. “The project development team integrated our sensor array technology onto the system, allowing automation of the highly selective DestiNA reaction and detection of any biomarker targets using the acoustic transducers.”

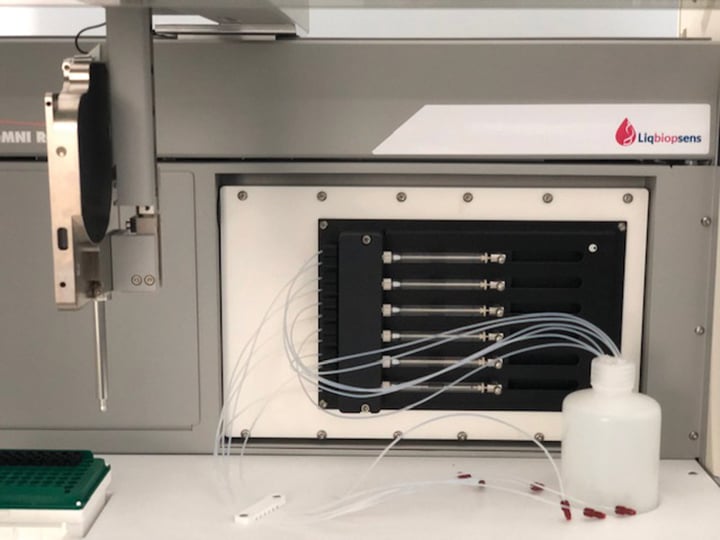

The Cavro XMP’s six-channel syringe pump manifold is used to provide a steady flow of fluids across the sensors

“Samples and reagents are delivered to the six independent channels of the sensing cartridge using the Cavro ADP, then the Cavro XMP’s six-channel syringe pump manifold is used to provide a steady flow of fluids across the sensors during the reactions. By including a 24-sensor array rather than the more commonly used single sensor, we have increased the throughput and number of analytes that can be simultaneously detected in a run. Accurate and precise pipetting throughout the process is essential for reliable, consistent results, as any variation in the volumes pipetted will have an impact on the reproducibility and quantitative accuracy of the experiments. Workflow automation is therefore key; it is much less laborious and time consuming than manual pipetting, and enables accurate and precise transfer of samples to the sensing device, eliminating the potential for human errors. The end-user simply has to load the workdeck and start the run.”

Workflow automation is therefore key; it is much less laborious and time consuming than manual pipetting, and enables accurate and precise transfer of samples to the sensing device.

“We have successfully developed a prototype automated platform based on the Cavro Omni Flex robot, combining our technology and the DestiNA chemistry to offer faster detection of oncogenic mutations than is possible with currently available enzyme-based assays, with fewer false positive results. This straightforward technique is now being evaluated by our Horizon 2020 partners, using patient samples in a ‘real world’ environment. Once fully validated, the system is set to deliver low cost, real-time detection of cancer markers in blood samples, benefitting both patients and healthcare providers,” said Maribel.

To find out more about Tecan’s Cavro Omni Flex, visit www.tecan.com/omniflex

To learn more about AWSensors, go to www.awsensors.com