The emergence and outbreak of the novel coronavirus SARS-CoV-2 at the end of 2019 has created an urgent need for testing to help limit the spread of COVID-19. AusDiagnostics has used its patented, multiplexed-tandem PCR technology to develop a test to detect SARS-CoV-2 and distinguish between the different causes of coronavirus-like infections.

Infectious diseases are one of the greatest threats to public health worldwide, with recent major outbreaks including Ebola, Zika and, most recently, SARS-CoV-2 (COVID-19). Molecular testing is essential for the detection of these RNA viruses, and Sydney-based AusDiagnostics supplies a range of highly multiplexed molecular tests used by the medical, veterinary, food, water and environmental sectors. Professor Keith Stanley, Managing Director, explained the company’s origins: “We launched AusDiagnostics in 2006 to commercialize a novel technique for multiplexing PCR. At the time, it was the start of the H5N1 (avian) influenza outbreak, so we were initially focused on designing tests and panels for microbiology. Since then, we have grown our product range to cover everything from respiratory diseases and food pathogens to cyanobacteria and cattle parasites. We pride ourselves on working closely with our customers to ensure they have a reagent kit that exactly matches their needs – including altering existing panels to meet national or regional legislation.”

“Our patented multiplexed-tandem PCR technology allows the detection of multiple targets in one sample, without compromising analytical sensitivity and specificity. Multiplexing offers a complete picture of what is wrong with a patient. For example, 10 to 15 percent of people have more than one infection at a time and, while their symptoms indicate one pathogen, they actually have a much higher level of something else entirely! It’s therefore much better to test for a complete panel of diseases, because if you test for just one – and you find a positive – the patient may only be treated for that indication, rather than the pathogen that is most important to treat.”

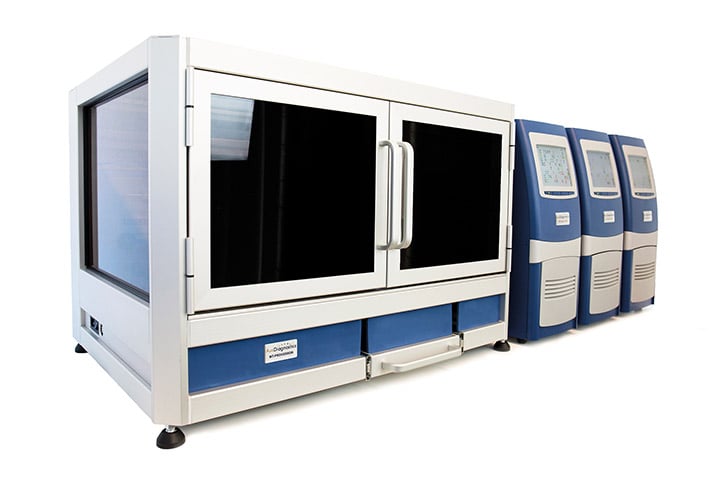

AusDiagnostics’ Ultra-Plex systems offer walkaway, multiplex processing for molecular detection

Following the outbreak of COVID-19, AusDiagnostics developed several kits that can be used to detect the presence of the SARS-CoV-2 virus. The fast spread of this novel coronavirus means that testing is vital to reduce transmission and distinguish between patients infected with COVID-19 and other infections with similar symptoms. Keith continued: “For each test we develop, we look for the best place to position our primers in the whole genome of the virus, and our validation studies show that our products are close to 100 percent sensitive and specific. Our main screening kit has two targets for SARS-CoV-2 plus influenza A, influenza B and RSV, while our other kits have 16 or 24 respiratory targets. Using two targets for SARS-CoV-2 on the one panel makes it very unlikely that a sample that is positive for both targets could be a false positive. Two different sets of primers – each consisting of four primers – have to bind, which requires eight separate hybridizations to get a positive result. A further advantage is that having two targets helps to protect against mutations. In a single target test, there is a danger of false negatives if your amplicon falls in the region where a mutation has occurred. By using two targets, we can look for drift in the ratio between targets in our customers’ data, to see if we can pick up changes that may be occurring. Our workflow also has two PCR steps, which has the advantage of making our test very sensitive, and so we pick up positives that even a reference lab may miss.”

The Cavro Air Displacement Pipettor (ADP) was a great solution, as it was ready made, reducing engineering research and speeding up the development of our full platform.

The company’s technology allowed it to respond very quickly to the COVID-19 crisis, positively testing its first clinical sample by the 31st of January – less than three weeks after the first sequence was published – and achieving CE marking by the beginning of March. Keith added: “We’re now producing a quarter of a million of these tests a month here in Australia, and another 150,000 a month in the UK. These tests are designed for throat or nasal swabs, and run on our bespoke molecular diagnostics systems.” Each of AusDiagnostics’ molecular diagnostic platforms consists of two main elements – a sample processor and a real-time PCR analyzer. When developing its latest platform – the Ultra-Plex 96 system, which launched in early 2020 – the company turned to Tecan to help reduce time to market. Keith continued: “The Ultra-Plex 96 can conduct a two-step PCR workflow in parallel, and it has a built-in 96-well thermal cycler on the workdeck. The system can run an assay panel with 768 individual PCR results in as little as 3.5 hours, with the ability to reload samples every two hours, making it perfect for the volume of samples that need to be screened during a pandemic. The automation reduces the risk of errors that are likely to occur if done manually; running a test is as simple as putting your name in, uploading the sample IDs, selecting the panel you’re going to run and pressing go.”

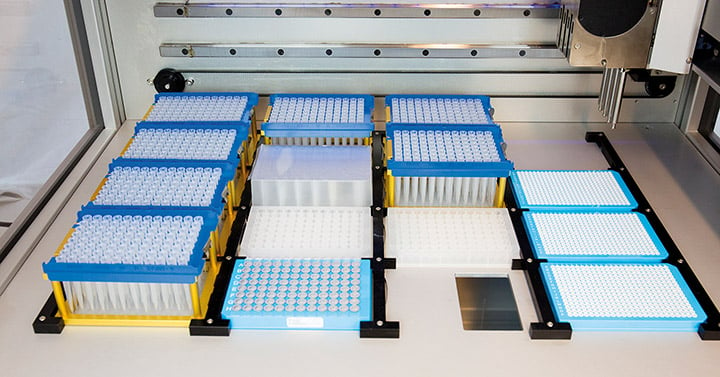

The AusDiagnostics Ultra-Plex 96 uses four Cavro ADPs to conduct a two-step PCR workflow in as little as 3.5 hours

The AusDiagnostics Ultra-Plex 96 uses four Cavro ADPs to conduct a two-step PCR workflow in as little as 3.5 hours

“We wanted to get this platform to market quickly, and decided to use an off-the-shelf pipetting mechanism. We turned to Tecan to meet this need because we were already using 10 Freedom EVO® 150 liquid handling workstations in the production of our kits, and so we trust the company’s technology inherently. The Cavro® Air Displacement Pipettor (ADP) was a great solution, as it was ready made, reducing engineering research and speeding up the development of our full platform. We had already developed some of our own pipetting heads, and so we could admire the cleverness of Tecan’s technology, as well as see that the component met our precision and reproducibility needs. We were able to easily integrate the ADP into our own robotic platform, and it communicates seamlessly via a USB port.” “There is huge demand for our platform at the moment, from both hospital and private laboratories; we are shipping to customers as quickly as we can. We appreciate the cooperation and collaboration that we have had from Tecan throughout this project, and the team has been very proactive in helping us to find the right solution at each phase. We were even alerted when Tecan started to offer clear disposable tips that would help us reduce the cost to our customers. The Tecan team has also helped with scheduling parts deliveries, checking our stock levels and delaying shipment if we weren’t ready or, more likely in the current situation, speeding up an order if we were running low. Our platform and kits are really making a difference in this pandemic, and Tecan has helped us to achieve this.”

To find out more about Tecan’s Cavro ADP, visit www.tecan.com/cavro-adp

To learn more about AusDiagnostics, go to www.ausdiagnostics.com

Keywords: