By Claudio Bui

When introducing a new product to the automated liquid handling market, getting there first with high quality and reliable hardware is vital to capturing and maintaining early market leadership. How can you gain that advantage when you have to balance requirements for customized high-performance robotics against an accelerated product launch?

Flexibility in choosing OEM liquid handling robotic components can be the key to minimizing time-to-market.

Here are six questions to consider that may help you avoid costly errors, save time, and ensure your product development process moves quickly and smoothly:

1. Is the liquid handling robotic component that you need readily available ?

Customization from scratch offers great flexibility, but defining specifications for each individual robotic component can be time consuming. Incorporating a complete liquid handling robotic instrument is efficient, but might not offer the configuration you need. To get the best of both worlds, configurable and modular OEM liquid handling robotic components may offer a simpler and faster solution to customization.

2. Can you integrate your robotic component into your system as soon as it arrives at your bench?

When your component arrives, you want to start integration right away so that you can move forward quickly with development. Components that are designed specifically for your application will help to simplify integration. Evaluate the mechanical, electronic, and software interfaces that will be required to connect your robotic component and begin communication with your platform.

3. How much testing will you need to do when your component arrives?

Performance validation is a necessary but often time- and resource-consuming process. Determine early in your project how much testing you might need to do to be confident that your robotic component will perform according to your specifications and for your applications. Any verification or validation that is done for you ahead of time can condense your in-house testing requirements and mitigate performance risks.

4. Is your robotic component ready for safety and regulatory compliance testing?

Unforeseen testing requirements to ensure safety and regulatory compliance can add unexpected delays, just when your team is eagerly anticipating product launch. Confirming ahead of time that your component complies with all metrics for safety, material usage (RoHs) and proper design and documentation requirements can help to reduce risk and streamline approval.

5. Will your component be available for as long as you need it?

Your product is expected to bring many years of value to your customers and your business. You should be in control of the lifetime of your products. When you select an OEM robotic component, confirm with your supplier that the component you have specifically selected will be available for as long as you need it.

6. How will your robotic component help to keep your customers’ systems running smoothly?

Trouble-free operation of your overall system comes from more than just meeting the specifications of the individual components. First, it comes from a supplier who has proven top quality performance. Second, it comes from extensive performance and compliance testing. Third, it comes from seamless integration of all of the components. Fourth, it comes from long-term reliability of component performance. Finally, it comes from a partner who is committed to each of these criteria. When you can rely on the performance and longevity of integrated liquid handling robotic components, you and your customers can be confident that they can operate without unexpected interruptions.

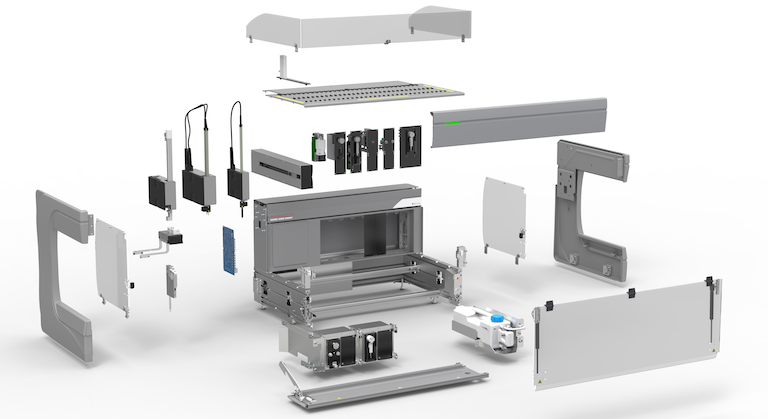

Delays in the development of complex automated liquid handling systems are often inevitable. The Cavro® Omni Flex configurator helps you to quickly and easily define best robotic component for your specific requirements so that you can ensure excellent performance for your customers over the long term. Quick configuration to get the right component can help you to keep your lab automation project on budget, on spec and on time for faster time-to-market and reliable operation for the lifetime of your product.

With the Tecan Cavro Omni Flex configurator you can quickly and easily combine your choice of XYZ axes, syringe pumps and microplate handling components with your Cavro Omni Robot, creating the customized automated liquid handling platform that you need to bring your products to market sooner.

Try the Cavro Omni Flex configurator now

About the author

Claudio Bui

Claudio Bui is the Head of Product Concepts for the Partnering Business in the Components Marketing Team. The primary function of his team is to work closely with customers to develop new concepts and proposals based on a thorough analysis of their specific requirements. Claudio started at Tecan in 1990 in R&D developing Components and has been involved in the development of a number of small laboratory instruments. In 2005, he joined the Marketing team.