By Kevin Moore

The repeatability of biomedical research has become a major issue, and the ability to achieve reproducible research results can only be as good as the liquid handling performance. Automation has become a given step in the drive to generate reproducible data so how well can automated liquid handling perform in, for example, genomics applications?

Tame variability with automated liquid handling

Measuring assay and method performance means looking into a wide range of characteristics such as analytical sensitivity, specificity, accuracy, reproducibility, linearity, limit of detection, and reportable range. This can be a real challenge in highly complex methods such as next generation sequencing (NGS), but a major component in the reproducibility of any method is having complete control over liquid handling.

How reproducible is your genomics research?

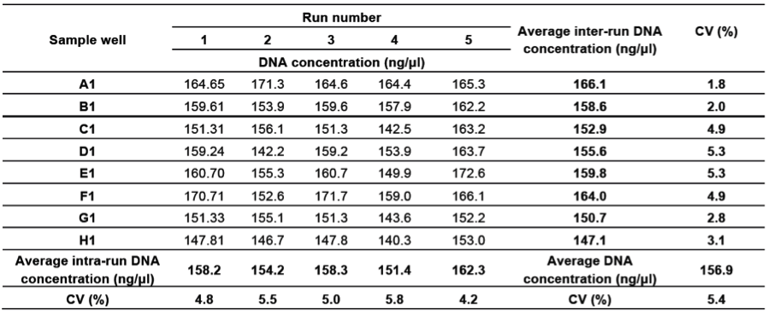

To show what can be achieved with automation of liquid handling, we can take a relatively simple yet crucial step in a genomics workflow as an example: the quantification of double-stranded DNA (dsDNA). In this example, dsDNA was determined using a fluorescence-based kit on samples in a 96-well format. Automated liquid handling was performed with an eight-channel air displacement arm and filtered disposable tips, together with a multimode reader placed under the plate. The reproducibility of data, based on five runs of eight replicates of a single sample, was 5.8% coefficient of variation (CV) or better, both within and across the five runs. Even if you can often achieve this level of precision with manual pipetting, automation can deliver this performance 24/7, eliminates the risk of human error, increases throughput, and also frees up lab staff from a tedious and time-consuming task.

Table 1: Consistency of standard curve preparation based on five runs of eight replicates for a single sample.

Checkerboards check for cross-contamination

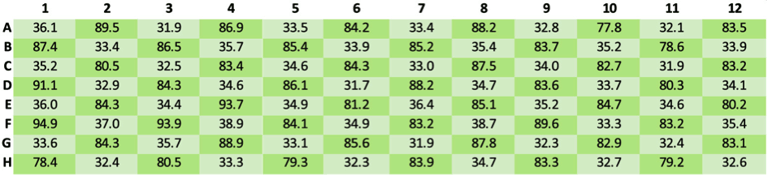

Testing liquid handling with a single sample will give valuable performance data, but real-life applications involve multiple samples, often with a wide range of concentrations. It is therefore critical to evaluate the risk of contamination between wells, for example between samples of high and low concentrations. Another important test is the checkerboard, where samples with high and low concentrations are placed in adjacent wells. In the example here, quantification results were also satisfactory when working with 48 high- and 48 low- concentration samples dispensed in a checkerboard pattern. Samples show consistent values throughout the plate, demonstrating that cross-contamination was not an issue.

Figure 1. Quantification results for the assessment of cross-contamination using the automated method. Darker shading, average concentration 84.7 ng/μL; lighter shading, average concentration 34.1 ng/μL.

Figure 1. Quantification results for the assessment of cross-contamination using the automated method. Darker shading, average concentration 84.7 ng/μL; lighter shading, average concentration 34.1 ng/μL.

Automatic normalization simplifies workflows and minimizes errors

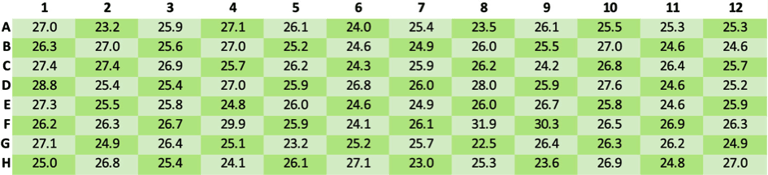

The final step in this quantification of dsDNA is to dilute the samples to the same concentration in order to simplify downstream processing. Certainly this can be done manually, but automating this step will save hands-on time and minimize errors. The data saved from the quantification step was used to automatically generate a script to achieve the desired concentration and volume for each sample, either in situ or in a separate plate. In this case, the average concentration of the normalized samples was 25.9 ng/μL, with a CV of only 5.5%, which would clearly be a great foundation on which to build reproducible data.

Figure 2. Normalized samples provide a good starting point for the next step in the workflow.

Figure 2. Normalized samples provide a good starting point for the next step in the workflow.

Tight control ensures adherence to SOPs

This performance in sample handling is a good basis for generating reproducible research. Added to that, automating liquid handling, quantification and normalization of samples ready for downstream steps means that standard operating procedures can be followed exactly. This means that you can achieve the same results time and time again.

Flexibility is vital in a research setting

With today’s automation technologies, you should not have to worry about constraining your lab work to a set pattern or protocol. Flexibility should go beyond simply offering you the choice between 96- and 384-well plates. Look for a user interface that combines ease of use with sufficient flexibility for a wide variety of different applications and workflows, such as post-purification QC or sample processing for NGS library preparation.

Whatever your application, automating the liquid handling will provide a solid and dependable foundation for generating reproducible research results and also help in speeding up your workflows.

Want to know more?

Find out what's coming soon in liquid handling automation systems.

References

- Application Note: Automation of the Quant-iT™ PicoGreen® dsDNA Assay Kit on the Fluent® Laboratory Automation Solution. Quantification and normalization of double stranded DNA with minimal set-up time.

About the author

Kevin Moore

Kevin Moore is Head of Markets and Applications based out of Tecan’s head office in Männedorf, Switzerland. He heads the team tasked with bringing both products and application for the liquid handling to the market. Prior to joining Tecan in 2007, he was head of Compound Management and Technology project manager for the Neuroscience Research Centre of Merck & Co in the UK, where he worked for Merck for 20 years.