By Markus Wiggli (in collaboration with Artel)

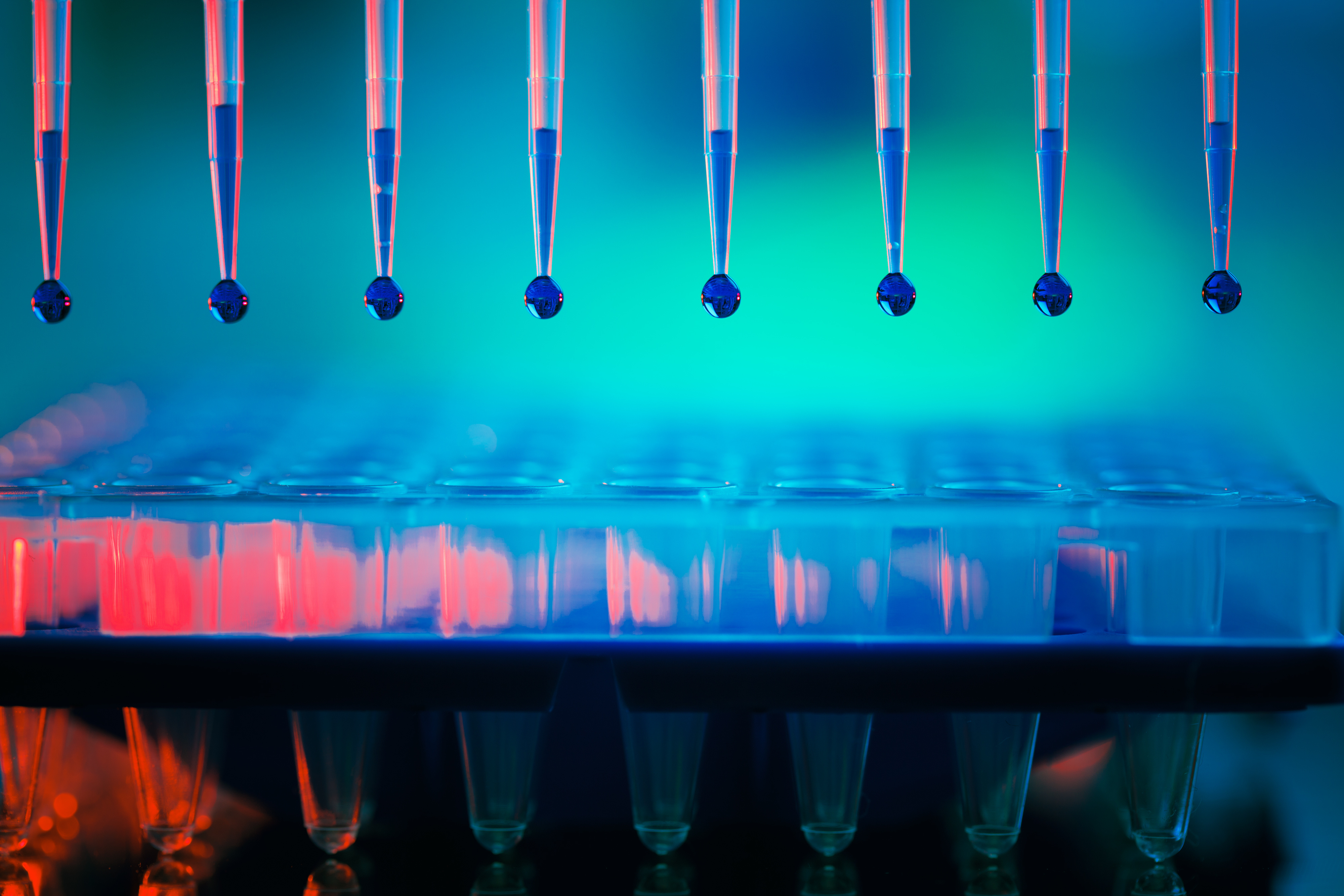

Imagine discovering that one of your company’s core liquid handling procedures has been generating variable results from one automation platform to the next, or one lab to the next. The impact could have devastating consequences for your work, if not for your career. Fortunately, an ISO quality standard has been established to help reduce the risk of this quality management nightmare becoming a reality.

A new ISO standard assures consistent results across automated liquid handling systems.

ISO/IWA 15 is a specification and method for determining the performance of automated liquid handling systems (ALHS). Standardization maximizes precision and reduces risks in processes. ISO requirements for standardization enhance the ability to compare performance across geographically disparate laboratories and different platforms. This is essential for optimal communication and confidence in the scientific data generated using ALHS.

In this Q&A session with industry leaders, we explore the importance of ISO/IWA 15 and the future of ISO performance standards for liquid handling automation. The conversation highlights how laboratories can use ISO/IWA 15 to reduce risk and improve quality control.

Q&A Session

Panelists: George Rodrigues (GR), Artel; A. Bjoern Carle (BC), Artel; Markus Wiggli (MW), Tecan

Q: What does IWA 15 stand for, and what exactly is it?

GR: IWA is the abbreviation for International Workshop Agreement. This is an ISO document type developed by a group of international technical experts that follows a faster timeline and more streamlined process compared to the typical ISO standards development process. ISO/IWA 15 addresses the needs of laboratories (end-users) and manufacturers, as well as calibration and service organizations, for ALHS.

Q: Is this something labs should be paying attention to now?

MW: Yes. ISO/IWA 15 is the first and only ISO document addressing volumetric performance testing of ALHS. There is currently no other international standard or guidance document available for evaluating the performance of ALHS.

Q: What is the focus of ISO/IWA 15?

BC: ISO/IWA 15 is a key step towards fully standardized ALHS performance measurements and evaluations. The focus of this IWA is the standardization of terminology, test methods, and interpretation of test results. This ensures that ALHS manufacturers, independent calibration and test services, and end-users are able to “speak the same language,” use the same test and evaluation methods, and compare test results.

As research, development, and manufacturing processes are increasingly performed by contractors and partners across vast geographies, we know that we need to communicate – and operate – with precision. The ability to test and compare the performance of ALHS across different platforms and between different labs is critical for confidence in, and inter-comparability of, scientific data generated using ALHS.

Q: How can labs and scientists use the information within IWA 15 to their advantage?

MW: Labs should select the test method described in ISO/IWA 15 that is most suitable to their work. For example, a test method may be selected based on the volumes to be transferred, plate and liquid types to be used, or requirements for lab equipment and environmental conditions. Once a test method has been chosen, the test results should be evaluated based on the statistical methods described in ISO/IWA 15. Following a standardized test protocol and statistical evaluation will allow scientists to compare the performance results of different ALHS, no matter where they are located – within the same building or around the globe.

Q: How does IWA 15 help labs to reduce risks in their processes?

GR: Full knowledge of volumetric performance is important for the correct evaluation of analytical test results. Ensuring that each ALHS is adjusted to the same performance level when performing the same task on different systems will provide consistency, and confidence, in the results. Reducing the risk of inconsistent outcomes due to inconsistent ALHS performance is a critical step towards an organization’s global quality policy.

Q: How will this impact, and potentially improve, the daily lives of labs using ALHS for their assays and processes?

BC: Each laboratory will most likely already have an SOP in place to address performance testing of their ALHS. However, these SOPs can vary dramatically from lab to lab, division to division, or site to site. Implementing universally recognized and applied test and evaluation methods in the SOPs across an entire organization will facilitate data comparisons, increase confidence in results, and reduce time to develop new ALHS performance test procedures for individual labs. Such standardization will save time and costs, while reducing the risk of questionable or incorrect results in critical lab processes.

Q: How does IWA 15 impact us as consumers, as those at the end of the value chain?

GR: That’s a great question and goes to the heart of the matter. Improved operations at clinical labs can provide faster, cheaper, and more accurate diagnostic results, allowing physicians to more quickly diagnose and treat their patients. A reduced rate of incorrect tests will lead directly to fewer misdiagnoses and incorrect treatments. Furthermore, the development of new drugs and vaccines can be accelerated with increased data integrity at all stages during the development processes. Ultimately, increased confidence in liquid handling performance can have large benefits to the general public – those who have the most at stake and pay the “final” bill.

Q: What can labs expect going forward?

BC: Each ISO IWA has a maximum life span of six years. The technical committee responsible for ISO/IWA 15 has already begun the development of a new ISO standard to succeed ISO/IWA 15. This new standard (ISO/CD 23783) is based directly on ISO/IWA 15, which means that laboratories that have implemented ISO/IWA 15 into their SOPs will have a head start in complying with the new ISO standard. Standardization of volumetric performance evaluation of ALHS will continue to be a critical part of any lab’s quality management program, and the ISO standard under preparation will continue to support that objective.

Q: How can the QC Kit/MVS® help to ensure compliance with ISO/IWA 15 and the upcoming ISO standard?

MW: Tecan’s QC Kit and the Artel MVS comply with the ratiometric photometric measurement method, which is described in ISO/IWA 15 and is a proposed test method in the upcoming ISO standard.

Q: Are there other benefits from volume verification with the QC Kit/MVS?

GR: Both the Tecan QC Kit and the Artel MVS are turnkey systems to evaluate the volumetric performance of ALHS. Each provides a combination of ready-to-use test liquids, dimensionally characterized 96- and 384-well microplates, and a calibrator plate, which ensures photometric performance of the plate reader. This produces volumetric measurements that are traceable to the International System of Units (SI). Standards maintained by the National Institute of Standards and Technology (NIST-US) and the National Physical Laboratory (NPL-UK) are used to achieve this traceability to the SI. The QC Kit and the MVS allow fast and easy evaluation and optimization of ALHS volumetric performance by a standardized test system in any lab, at any time, and in any location. This is the essence of global standardization of ALHS quality management, and the key to optimal lab productivity and quality.

Summary

To maximize the advantages of ISO/IWA 15, laboratories can select a test method that is best suited to their work. By following a standardized test protocol and statistical evaluation, different liquid handling systems can be compared, no matter their location.

Use of ISO standardization tools within a laboratory can reduce the risk of inconsistent outcomes. Tecan’s QC Kit and Artel’s MVS are turnkey systems to evaluate the volumetric performance of ALHS that comply with a test method described in ISO/IWA 15. Find out more about Tecan’s quality assurance solutions and tools.

Acknowledgements

This blog was written in collaboration with Artel. Participating panelists from Artel include George Rodrigues and Bjoern Carle.

About the author

Dr. Markus Wiggli

Dr. Markus Wiggli joined Tecan in 1998 and worked on the development of the liquid handling of several platform generations. Later, he helped to develop and improve blood typing instruments (partnering business). Now, as a Senior Liquid Handling Scientist, he develops and supports application solutions for the partnering business. He studied Biology at the Biozentrum Basel (University), and holds a PhD of the University of Zürich.