By Agnieszka Sitarska

Whatever you are using automated liquid handling for, be it drug development, next generation sequencing, assay development or basic research with cell-based assays, getting correct results is crucial to reaching your goals, quickly and efficiently. And you also need to prove the validity of your data for regulatory compliance. The question is, how can this be achieved with little effort?

A standardized approach for assuring pipetting accuracy is essential for regulated procedures.

Build in quality from the very beginning

Being efficient means getting accurate data with a minimum of effort. You can start by implementing QC methods into an effective quality control program in your laboratory. A robust liquid-handling quality control program will build quality into your processes that decreases costs by improving data quality and shortening timelines, thanks to fewer re-runs and false leads.

Standardized calibration eases assay transfer

Regular standardized calibration of liquid handling instruments is one of the most effective ways of securing reliable data. It is not uncommon that as organizations grow, each department develops its own calibration methods and discrepancies between procedures can lead to problems in assay transfer and comparison of data. Standardization ensures consistency across organizations and eases assay transfer between departments and sites.

QC kits to support the process

Any help in standardization can be welcome, and using a QC kit is one way to ease the way to obtaining consistently reliable results and ensuring regulatory compliance. Using a kit would ensure standardization of the basic components of the QC process across the organization. And with the right ingredients, results can be traceable to the International System of Units (SI), through reference standards maintained by NIST (in the US) and NPL (in the UK).

Find out more about quality assurance with Tecan’s QC Kit

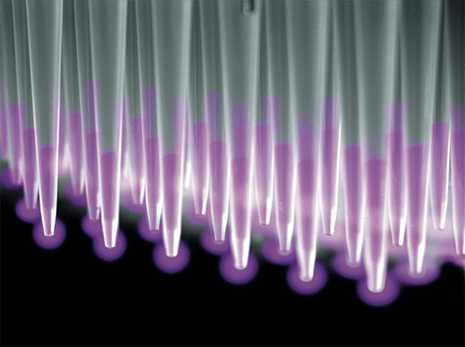

Our QC Kit is a quality control tool for pipetting volume verification of your liquid handling platform, ensuring full regulatory compliance. The kit incorporates the proprietary Ratiometric Photometry technology of Artel, the worldwide leader in liquid handling quality assurance.

About the author

Agnieszka Sitarska

Agnieszka Sitarska is a junior product manager for consumables at Tecan Männedorf. She studied Biotechnology at Jagiellonian University in Krakow, Poland, and completed her Master’s thesis at Novartis Institute for Biomedical Research in Basel, Switzerland. After her studies, she worked in the pharmaceutical industry, gaining experience in business support, before joining Tecan in July 2016.