By Kevin Moore

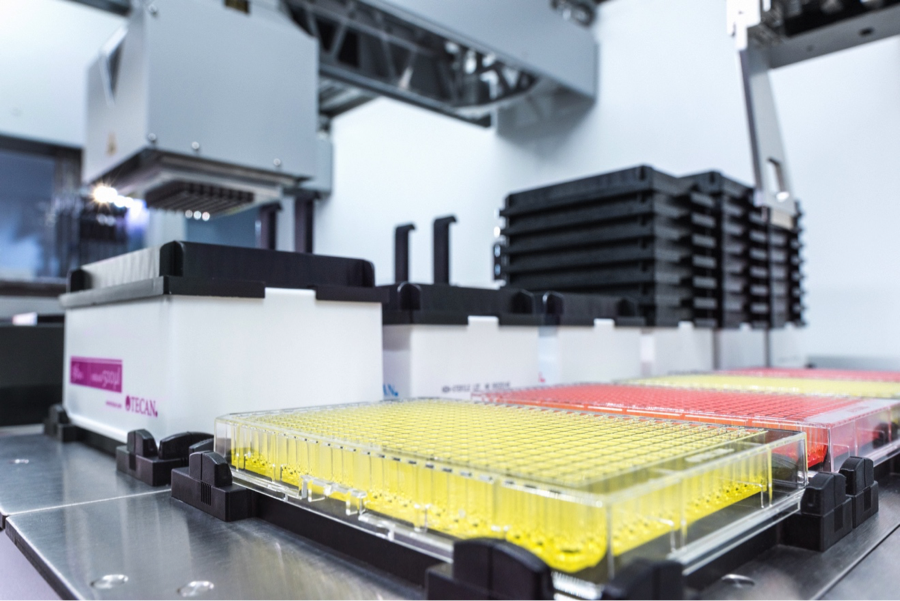

When looking to maximize productivity in life science R&D, drug discovery, clinical studies or clinical diagnostics, laboratory automation is a crucial element. You may already have identified great solutions to automate individual applications and steps in your workflows, but unless these systems work together harmoniously, your lab’s overall productivity could still fall short of the mark. Whether your application area involves clinical diagnostics, genomics, cell biology, drug discovery, protein purification or something else altogether, we’ve identified some of the most common roadblocks to successful automation.

Simplify your lab and increase productivity with industry-leading, application-focused automation.

Take these 4 common pitfalls into account when deciding which of the many available automation solutions is right for your needs:

1. Integration frustration between vendors

In an automated process, every single element needs to pull its weight, and the overall efficiency is only as good as the weakest link. While it is often convenient to automate individual applications and tasks using devices from a range of different vendors or manufacturers, the resulting lack of integration is a common source of problems. Integrating new instruments and components with each other, or with your existing equipment, can be frustrating and time-consuming. Even when you achieve a working solution, the various devices in your workflow may not be supported to the same level by the different vendors; it only takes one faulty element to compromise results and bring your entire process to a halt while you wait for a support specialist to become available.

The answer? Whenever possible, it makes sense to source automated solutions from a single trusted manufacturer or vendor, and to look for platforms that can encompass the entire workflow from start to finish. Since your needs can easily change as protocols are updated and new technologies come on board, consider investing in an open automation platform that provides flexibility for different peripheral devices, configurations and protocols.

For example, many labs doing next generation sequencing (NGS) go to the trouble and expense of automating library preparation, but still perform DNA quantification and normalization steps manually or on separate platforms. This means that the overall workflow is discontinuous and decentralized across several devices—all of which creates delays, extra work, and opportunities for error. Open automation systems, like Tecan’s Freedom Evo® and Fluent® platforms, can enable many different configurations and interface with a wide variety of devices, so that you can automate more of the NGS workflow and control the process through a single interface. Tecan experts work closely with vendors like Illumina and ThermoFisher to develop and road-test compatible protocols that enable end-to-end automation of leading NGS sample and library preparation kits on Tecan platforms.

2. Quality gaps

Inconsistent performance of different systems can introduce hidden variability into your results and have a catastrophic effect on productivity. Attention to detail and focus on quality may vary greatly between different manufacturers and different automation solutions. Moreover, novel protocols and applications may place devices in a new context that pushes them beyond intended performance limits. Individual devices may be efficient at what they were designed to do, but who is looking at quality across the whole workflow?

Cell-based assays, for instance, can be particularly sensitive to changes in temperature and humidity. In a typical cell-based assay it is not unusual to be moving the cells between multiple devices for liquid handling, incubation and detection. It is much easier to maintain high cell assay performance if you run your assays using solutions developed by a single supplier with a keen eye for quality.

For example, Tecan’s Spark® multimode reader can be fitted with modular environmental control and integrated with peripheral equipment such as culture incubators, plate stackers and liquid handling devices, so that you can incubate, dispense and read with minimal disruption of the environment of your cells. With consistent and reliable regulation of temperature, gas and humidity provided by Spark’s modular environmental control unit, you can run assays over the course of several days while minimizing environmental fluctuations, evaporation, and the risk of contamination.

3. User-interface overload

Automating processes by putting together equipment from different manufacturers or vendors results in a range of different user interfaces that lab personnel have to master. Not only is it aggravating to have to switch from one interface to another, the added complication can lead to costly mistakes. Adopting a common user interface for multiple pieces of equipment can make life much easier, reducing the risk of error as well as the training burden.

Open-architecture automation solutions can help you coordinate the devices in your workflow through a single interface. When deciding on which platform to go with, it also makes sense to look across the manufacturer’s product range to see whether compatibility across platforms and software packages is a priority for them. For instance, the open architecture of EVOware® enables software elements to be added as needed to expand functionality without adding new user interfaces. Wizard guides can also be a big help, especially when you are getting a new process up and running. For example, the Freedom EVOware Te-Chrom™ Wizard guides users through a chromatography set-up step-by-step, generating ready-to-run protocols.

Both EVOware and the Fluent Gx Automation Workstation offer an alternative interface to wizards – a touchscreen interface that simplifies daily activities by providing visual guides to lead you through routine system set-up and operation, and also complex tasks. The result is consistent and reproducible performance and easier compliance with standard operating procedures without the need for advanced training.

4. A tortuous route to compliance

Validating automated workflows and achieving compliance in the regulated lab is challenging enough, but achieving this with a combination of solutions can be even more complicated and time consuming. Choosing a compliance-ready system that provides the flexibility you need to cover a wide range of applications and laboratory developed tests will help you navigate the difficult route to compliance and give you confidence in the outcome.

Tecan has developed the Fluent Gx Automation Workstation with compliance in mind, designing it specifically to meet the needs of regulated laboratories, with all the advanced process security features required for applications in clinical, GMP and QC facilities. Fluent Gx Assurance Software is a suite of software features needed to comply and demonstrate compliance with stringent regulatory requirements, including FDA 21 CFR Part 11.

Automation roadblocks? Let Tecan show you the way.

In short, when considering lab automation, look for a well-established manufacturer that has trusted equipment to meet a broad range of applications. It also pays to think in advance about the level of expert support available to help you integrate your workflows and get them up and running quickly.

No matter what your application, Tecan’s versatile portfolio of automation solutions can help you:

- Do more in less time

- Run processes unattended (walkaway automation)

- Do more with smaller sample volumes

- Improve experimental reproducibility

- Reduce reagent consumption

- Increase accuracy and precision, reduce errors, and improve data quality

- Run compliant processes

Added to that, the Tecan Labwerx can help you to integrate numerous instruments into a customized Tecan system that meets your particular needs.

Download our liquid handling buyer’s guide to help you with decision-making.

About the author

Kevin Moore

Kevin Moore is Head of Markets and Applications based out of Tecan’s head office in Männedorf, Switzerland. He heads the team tasked with bringing both products and application for the liquid handling to the market. Prior to joining Tecan in 2007, he was head of Compound Management and Technology project manager for the Neuroscience Research Centre of Merck & Co in the UK, where he worked for Merck for 20 years.